Abstract

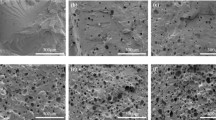

Our previous work demonstrated that the powder flowability of a cohesive lactose sample can be improved substantially using a dry coating technique. Our study reported here aims to investigate the influence of host particle size on the modification of powder flowability following dry coating process. Four commercial lactose monohydrate powders with different particle sizes were coated by an intensive mechanical process or mixed using a conventional tumbling process, both with magnesium stearate. All four untreated lactose samples showed a relatively poor powder flow. After dry coating, poured and tapped densities of all the lactose samples increased, while Carr indices and Hausner ratios decreased substantially. The angle of repose values were reduced to a notable extent only for particles with a median size larger than about 7 μm after dry coating. Both specific energy (SE) and cohesion values of lactose samples, measured by a powder rheometer system, decreased substantially after coating. In contrast, no apparent changes in powder flow were evident for conventionally mixed batches, except that in the dynamic powder rheometry measurement, a relatively small change in SE was observed. This study demonstrated that for the finer particles examined, cohesive forces were more influential in the powder bed after the surface treatment and resulted in a relatively poor flow. However, for the larger powders studied, the cohesive inter-particle forces could be overcome after this dry coating, whereby satisfactory flow could be obtained. This study indicated that the host particle size was a critical factor in influencing the modification of cohesive powder flowability.

Abstract

Carr Hausner 7 μm

Résumé

Quatre poudres commerciales de lactose monohydraté ont été enrobées à sec par mécanofusion et mélangées avec du stéarate de magnésium de façon conventionnelle dans un tambour. Avant traitement, les quatre échantillons de lactose non traité présentaient des propriétés d’écoulement relativement faibles. Après enrobage à sec, les masses volumiques, apparente et tassée, de tous les échantillons de lactose augmentaient tandis que les indices de Carr et les ratios d’Hausner diminuaient nettement. Les plus grands changements de masse volumique étaient trouvés pour les échantillons de lactose ayant une taille de particules médiane entre 7 et 20 μm. L’angle de repos était réduit de façon beaucoup plus importante pour les particules ayant une taille médiane supérieure 7 μm. L’énergie spécifique et les valeurs de cohésion des échantillons de lactose mesurées à l’aide d’un rhéomètre à poudres diminuaient substantiellement après enrobage. Au contraire, aucun changement apparent dans l’écoulement de la poudre n’était évident pour les lots mélangés en tambour, si ce n’est que, dans les mesures dynamiques de rhéométrie de la poudre, un déplacement limité de l’énergie spécifique était observé. Cette étude démontre que pour les petites particules, les forces cohésives sont influentes dans le lit de poudre, même après traitement de surface et résultent dans un relativement faible écoulement. Cependant, les poudres de plus grosse taille étudiées ont démontré que les forces de cohésion inter-particulaires à l’intérieur de la poudre d’origine pouvaient être surmontées et qu’un écoulement satisfaisant pouvait être obtenu après enrobage à sec. Dans ces séries de poudres de lactose, il a été montré pour la première fois dans cette étude qu’il semble y avoir une taille de particule critique pour laquelle une amélioration fonctionnelle significative de l’écoulement de la poudre peut être obtenue à l’aide de la nouvelle approche d’enrobage à sec. La rhéométrie de la poudre a été démontrée comme étant capable de détecter des différences fines dans le comportement de la poudre à l’écoulement, que des méthodes traditionnelles n’étaient pas capables d’obtenir.

Similar content being viewed by others

References

Abdullah E.C., Geldart D., The use of bulk density measurements as flowability indicators, Powder Technol. 102 (1999) 151–165.

Adi H., Larson I., Chiou H., Young P., Traini D., Stewart P., Agglomerate strength and dispersion of salmeterol xinafoate from powder mixtures for inhalation, Pharm. Res. 23 (2006) 2556–2565.

Adi H., Larson I., Stewart P., Laser diffraction particle sizing of cohesive lactose powders, Powder Technol. 179 (2007) 90–94.

Alonso M., Satoh M., Miyanami K., Mechanism of the combined coating — mechanofusion processing of powders, Powder Technol. 59 (1989) 45–52.

Alvarez R.C., Ageorges H., Fauchais P., Fournier P., Smith A., The effect of mechanofusion process and planetary-milling on composite powder preparation: agglomeration and fragmentation, Mater. Sci. Forum. 442 (2003) 67–72.

Amidon G.E., Bergren M.S., Grant D.J.W., Marshall K., Itai S., Physical test methods for powder flow characterization of pharmaceutical materials: a review of methods stimuli to the revision process, Pharmacopeial Forum 25 (1999) 8298–8308.

Begat P., Price R., Harris H., Morton D.A.V., Staniforth J.N., The influence of force control agents on the cohesive-adhesive balance in dry powder inhaler formulations, KONA Powder Part. J. 23 (2005) 109–121.

Bose S., Bogner R.H., Solventless pharmaceutical coating processes: a review, Pharm. Dev. Technol. 12 (2007) 115–131.

Carr R.L., Evaluating flow properties of solids, Chem. Eng. 72 (1965) 163–168.

Castellanos A., The relationship between attractive interparticle forces and bulk behaviour in dry and uncharged fine powders, Adv. Phys. 54 (2005) 263–376.

Chen W.L., Dave R.N., Pfeffer R., Walton O., Numerical simulation of Mechanofusion system, Powder Technol. 146 (2004) 121–136.

Dave R., Chen W.L., Mujumdar A., Wang W.Q., Pfeffer R., Numerical simulation of dry particle coating processes by the discrete element method, Adv. Powder Technol. 14 (2003) 449–470.

Freeman R., Measuring the flow properties of consolidated conditioned and aerated powders — A comparative study using a powder rheometer and a rotational shear cell, Powder Technol. 174 (2007) 25–33.

Geldart D., Types of gas fluidization, Powder Technol. 7 (1973) 285–292.

Hausner H.H., Friction conditions in a mass of metal powder, Int. J. Powder Metall. 3 (1967) 7–13.

Hou H., Sun C.C., Quantifying effects of particulate properties on powder flow properties using a ring shear tester, J. Pharm. Sci. 97 (2008) 4030–4039.

Iida K., Hayakawa Y., Okamoto H., Danjo K., Leuenberger H., Evaluation of flow properties of dry powder inhalation of salbutamol sulfate with lactose carrier, Chem. Pharm. Bull. 49 (2001) 1326–1330.

Jiang Y.B., Matsusaka S., Masuda H., Yokoyama T., Evaluation of flowability of composite particles and powder mixtures by a vibrating capillary method, J. Chem. Eng. Jpn. 39 (2006) 14–21.

Jones M.D., Price R., The influence of fine excipient particles on the performance of carrier-based dry powder inhalation formulations, Pharm. Res. 23 (2006) 1665–1674.

Kim E.H.J., Chen X.D., Pearce D., Effect of surface composition on the flowability of industrial spray-dried dairy powders, Colloids Surf. B 46 (2005) 182–187.

Kumon M., Machida S., Suzuki M., Kusai A., Yonemochi E., Terada K., Application and mechanism of inhalation profile improvement of DPI formulations by mechanofusion with magnesium stearate, Chem. Pharm. Bull. 56 (2008) 617–625.

Kumon M., Suzuki M., Kusai A., Yonemochi E., Terada K., Novel approach to DPI carrier lactose with mechanofusion process with additives and evaluation by IGC, Chem. Pharm. Bull. 54 (2006) 1508–1514.

Li Q., Rudolph V., Weigl B., Earl A., Interparticle van der Waals force in powder flowability and compactibility, Int. J. Pharm. 280 (2004) 77–93.

Morton D., Dry powder inhaler formulations comprising surface-modified particles with anti-adherent additives, US Pat. No. 0127972 A1, 2008.

Naito M., Kondo A., Yokoyama T., Applications of comminution techniques for the surface modification of powder materials, Iron Steel Inst. Jpn. Int. 33 (1993) 915–924.

Pfeffer R., Dave R.N., Wei D.G., Ramlakhan M., Synthesis of engineered particulates with tailored properties using dry particle coating, Powder Technol. 117 (2001) 40–67.

Pilpel N., The flow properties of magnesia, J. Pharm. Pharmacol. 16 (1964) 705–716.

Raula J., Laehde A., Kauppinen E.I., A novel gas phase method for the combined synthesis and coating of pharmaceutical particles, Pharm. Res. 25 (2008) 242–245.

Rowe R.C., Sheskey P.J., Owen S., Handbook of pharmaceutical excipients, Pharmaceutical Press, London, UK, 2006.

Schwedes J., Review on tester for measuring flow properties of bulk solids, Granular Matter 5 (2001) 1–43.

Sun C.C., Improving powder flow properties of citric acid by crystal hydration, J. Pharm. Sci. 98 (2009) 1744–1749.

Swaminathan V., Cobb J., Saracovan I., Measurement of the surface energy of lubricated pharmaceutical powders by inverse gas chromatography, Int. J. Pharm. 312 (2006) 158–165.

Thalberg K., Lindholm D., Axelsson A., Comparison of different flowability tests for powders for inhalation, Powder Technol. 146 (2004) 206–213.

Valverde J.M., Castellanos A., Ramos A., Watson P.K., Avalanches in fine, cohesive powders, Phys. Rev. E 62 (2000) 6851–6860.

Yang J., Sliva A., Banerjee A., Dave R.N., Pfeffer R., Dry particle coating for improving the flowability of cohesive powders, Powder Technol. 158 (2005) 21–33.

Yokoyama T., Urayama K., Maito M., Kato M., Yokoyama T., The angmill mechanofusion system and its applications, KONA Powder Part. J. 5 (1987) 59–68.

Zhou Q., Armstrong B., Larson I., Stewart J.P., Morton A.V.D., Improving powder flow properties of a cohesive lactose monohydrate powder by intensive mechanical dry coating, J. Pharm. Sci. (2009) DOI: 10.1002/jps.21885.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Zhou, Q., Armstrong, B., Larson, I. et al. Effect of host particle size on the modification of powder flow behaviours for lactose monohydrate following dry coating. Dairy Sci. Technol. 90, 237–251 (2010). https://doi.org/10.1051/dst/2009046

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1051/dst/2009046