Abstract

Lower olefins—generally referring to ethylene, propylene and butylene—are basic carbon-based building blocks that are widely used in the chemical industry, and are traditionally produced through thermal or catalytic cracking of a range of hydrocarbon feedstocks, such as naphtha, gas oil, condensates and light alkanes1,2. With the rapid depletion of the limited petroleum reserves that serve as the source of these hydrocarbons, there is an urgent need for processes that can produce lower olefins from alternative feedstocks3,4,5,6,7,8,9. The ‘Fischer–Tropsch to olefins’ (FTO) process has long offered a way of producing lower olefins directly from syngas—a mixture of hydrogen and carbon monoxide that is readily derived from coal, biomass and natural gas3,4,5,6,7. But the hydrocarbons obtained with the FTO process typically follow the so-called Anderson–Schulz–Flory distribution, which is characterized by a maximum C2–C4 hydrocarbon fraction of about 56.7 per cent and an undesired methane fraction of about 29.2 per cent (refs 1, 10, 11, 12). Here we show that, under mild reaction conditions, cobalt carbide quadrangular nanoprisms catalyse the FTO conversion of syngas with high selectivity for the production of lower olefins (constituting around 60.8 per cent of the carbon products), while generating little methane (about 5.0 per cent), with the ratio of desired unsaturated hydrocarbons to less valuable saturated hydrocarbons amongst the C2–C4 products being as high as 30. Detailed catalyst characterization during the initial reaction stage and theoretical calculations indicate that preferentially exposed {101} and {020} facets play a pivotal role during syngas conversion, in that they favour olefin production and inhibit methane formation, and thereby render cobalt carbide nanoprisms a promising new catalyst system for directly converting syngas into lower olefins.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Torres Galvis, H. M. & de Jong, K. P. Catalysts for production of lower olefins from synthesis gas: a review. ACS Catal. 3, 2130–2149 (2013)

Corma, A., Melo, F. V., Sauvanaud, L. & Ortega, F. Light cracked naphtha processing: controlling chemistry for maximum propylene production. Catal. Today 107–108, 699–706 (2005)

Torres Galvis, H. M. et al. Supported iron nanoparticles as catalysts for sustainable production of lower olefins. Science 335, 835–838 (2012)

Torres Galvis, H. M. et al. Iron particle size effects for direct production of lower olefins from synthesis gas. J. Am. Chem. Soc. 134, 16207–16215 (2012)

Koeken, A. C. J., Torres Galvis, H. M., Davidian, T., Ruitenbeek, M. & de Jong, K. P. Suppression of carbon deposition in the iron-catalyzed production of lower olefins from synthesis gas. Angew. Chem. Int. Ed. 51, 7190–7193 (2012)

Torres Galvis, H. M. et al. Effects of sodium and sulfur on catalytic performance of supported iron catalysts for the Fischer–Tropsch synthesis of lower olefins. J. Catal. 303, 22–30 (2013)

Santos, V. P. et al. Metal organic framework-mediated synthesis of highly active and stable Fischer–Tropsch catalysts. Nature Commun. 6, 6451 (2015)

Jiao, F. et al. Selective conversion of syngas to light olefins. Science 351, 1065–1068 (2016)

Cheng, K. et al. Direct and highly selective conversion of synthesis gas to lower olefins: design of a bifunctional catalyst combining methanol synthesis and carbon-carbon coupling. Angew. Chem. Int. Ed. 55, 4725–4728 (2016)

de Smit, E. & Weckhuysen, B. M. The renaissance of iron-based Fischer–Tropsch synthesis: on the multifaceted catalyst deactivation behaviour. Chem. Soc. Rev. 37, 2758–2781 (2008)

Zhang, Q., Kang, J. & Wang, Y. Development of novel catalysts for Fischer–Tropsch synthesis: tuning the product selectivity. ChemCatChem 2, 1030–1058 (2010)

van der Laan, G. P. & Beenackers, A. A. C. M. Kinetics and selectivity of the Fischer–Tropsch synthesis: a literature review. Catal. Rev. 41, 255–318 (1999)

Lu, J. et al. Promotion effects of nitrogen doping into carbon nanotubes on supported iron Fischer–Tropsch catalysts for lower olefins. ACS Catal. 4, 613–621 (2014)

Liu, Y., Chen, J., Bao, J. & Zhang, Y. Manganese-modified Fe3O4 microsphere catalyst with effective active phase of forming light olefins from syngas. ACS Catal. 5, 3905–3909 (2015)

Zhou, X. et al. Hierarchical structured α-Al2O3 supported S-promoted Fe catalysts for direct conversion of syngas to lower olefins. Chem. Commun. 51, 8853–8856 (2015)

Chen, X., Deng, D., Pan, X., Hu, Y. & Bao, X. N-doped graphene as an electron donor of iron catalysts for CO hydrogenation to light olefins. Chem. Commun. 51, 217–220 (2015)

Cheng, Y. et al. Fischer–Tropsch synthesis to lower olefins over potassium-promoted reduced graphene oxide supported iron catalysts. ACS Catal. 6, 389–399 (2016)

Mohandas, J. C. et al. Fischer–Tropsch synthesis: characterization and reaction testing of cobalt carbide. ACS Catal. 1, 1581–1588 (2011)

Cheng, J. et al. Density functional theory study of iron and cobalt carbides for Fischer–Tropsch synthesis. J. Phys. Chem. C 114, 1085–1093 (2010)

Pei, Y. P. et al. High alcohols synthesis via Fischer−Tropsch reaction at cobalt metal/carbide interface. ACS Catal. 5, 3620– 3624 (2015)

Karaca, H. et al. Structure and catalytic performance of Pt-promoted alumina-supported cobalt catalysts under realistic conditions of Fischer−Tropsch synthesis. J. Catal. 277, 14–26 (2011)

Claeys, M. et al. In situ magnetometer study on the formation and stability of cobalt carbide in Fischer–Tropsch synthesis. J. Catal. 318, 193–202 (2014)

Kwak, G. et al. In situ monitoring during the transition of cobalt carbide to metal state and its application as Fischer–Tropsch catalyst in slurry phase. J. Catal. 307, 27–36 (2013)

Huo, C. F. et al. The mechanism of potassium promoter: enhancing the stability of active surfaces. Angew. Chem. Int. Ed. 50, 7403–7406 (2011)

Lillebø, A. H., Patanou, E., Yang, J., Blekkan, E. A. & Holmen, A. The effect of alkali and alkaline earth elements on cobalt based Fischer–Tropsch catalysts. Catal. Today 215, 60–66 (2013)

Johnson, G. R., Werner, S. & Bell, A. T. An investigation into the effects of Mn promotion on the activity and selectivity of Co/SiO2 for Fischer–Tropsch synthesis: evidence for enhanced CO adsorption and dissociation. ACS Catal. 5, 5888–5903 (2015)

Feltes, T. E. et al. Selective adsorption of manganese onto cobalt for optimized Mn/Co/TiO2 Fischer–Tropsch catalysts. J. Catal. 270, 95–102 (2010)

Boultif, A. & Louër, D. Indexing of powder diffraction patterns for low-symmetry lattices by the successive dichotomy method. J. Appl. Cryst. 24, 987–993 (1991)

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 47, 558–561 (1993)

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996)

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994)

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999)

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996)

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976)

Sun, K., Zhao, Y., Su, H. Y. & Li, W. X. Force reversed method for locating transition states. Theor. Chem. Acc. 131, 1118–1127 (2012)

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000)

Henkelman, G. & Jónsson, H. Improved tangent estimate in the nudged elastic band method for finding minimum energy paths and saddle points. J. Chem. Phys. 113, 9978–9985 (2000)

Acknowledgements

This work has been supported by the Natural Science Foundation of China (grants 21403278, 21403277, 21573271, 91545112), the Shanghai Municipal Science and Technology Commission, China (grants 15DZ1170500, 14ZR1444600), Shanxi Lu’an Coal Corporation Limited, the Ministry of Science and Technology of China (grant 2016YFA0202802) and the Chinese Academy of Sciences (grant QYZDB-SSW-SLH035, the Youth Innovation Promotion Association of CAS).

Author information

Authors and Affiliations

Contributions

L.Z. and Y.S. designed the study, analysed the data and wrote the paper. F.Y. and Y.A. prepared the samples and drafted the manuscript. Y.Z. performed DFT calculations. Z.L. and T.L. studied the promoter effect. Y.L., X.Q. and Y.D. performed catalytic evaluation. L.G., J.H., S.J., Q.S. and H.W. characterized the samples. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Reviewer Information

Nature thanks M. Claeys, A. Holmen and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Extended data figures and tables

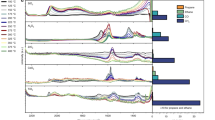

Extended Data Figure 1 Distribution of products generated by the FTO process from syngas.

a, Product distribution according to the Anderson–Schulz–Flory (ASF) model. The vertical bar shows the calculated hydrocarbon distribution for a chain-growth probability (α) of 0.46, which provides the highest proportion of C2–C4 hydrocarbons. b, Hydrocarbon distribution according to the ASF model for chain-growth probabilities of 0.3, 0.4, 0.46, 0.5, 0.6 and 0.7. c–e, Typical product plots obtained using our CoMn catalyst (showing ln(Wn/n) versus n) when the reaction was performed under a H2/CO ratio of 2 (c), 1 (d) or 0.5 (e), at a temperature of 250 °C and a pressure of 1 bar. The chain-growth probabilities were obtained by fitting the results obtained for C3–7 using the ASF model.

Extended Data Figure 2 Stability test for the CoMn catalyst.

Reaction conditions: 250 °C, 3 bar, 6,000 ml h−1 gcat−1, H2/CO = 1. The selectivity of the indicated products remains more or less constant over more than 600 h.

Extended Data Figure 3 X-ray diffraction analysis of the CoMn catalyst at different times on-stream.

a–g, Results from refinement of the X-ray diffraction patterns of catalysts at 0 h (a), 2 h (b), 4 h (c), 10 h (d), 15 h (e), 20 h (f) and 150 h (g) (‘0 h’ refers to the catalyst after reduction). The graphs show the different phases of the catalyst (Co, Co2C, CoxMn1−xO and MnO) that are present at different times on-stream. h, Quantification of the refinement results on the basis of a full Rietveld analysis. NA, not available.

Extended Data Figure 4 Catalytic performance and structure of Co2C sphere-like nanoparticles.

a, Catalytic performance of Co2C sphere-like nanoparticles with time on-stream. b, XRD pattern, c, TEM image and d, high-resolution TEM image of Co2C sphere-like nanoparticles. The Co2C was prepared by carbonizing Co3O4 with pure CO at a temperature of 250 °C and at atmospheric pressure for 24 h. The reaction was performed at 250 °C, 1 bar, 2,000 ml h−1 gcat−1, H2/CO = 2. The calculated reaction rate for such Co2C sphere-like nanoparticles was 2.8 × 10−3 mol CO h−1 gcat−1 for a CO conversion of 9.5%. The calculated reaction rate for the Co2C catalyst in ref. 18 was 8.9 × 10−4 mol CO h−1 gcat−1 (CO conversion of 2%, at 20 bar, 220 °C, 3,000 ml h−1 gcat−1, H2/CO = 2). The calculated reaction rate for the studied Co2C nanoprism catalyst was 9.4 × 10−3 mol CO h−1 gcat−1 (CO conversion of 31.8% at 250 °C, 1 bar, 2,000 ml h−1 gcat−1, H2/CO = 2).

Extended Data Figure 5 TEM images of the CoMn catalyst after reaching steady state.

a–d, Low-resolution images (a, b) and high-resolution images (c, d) showing Co2C nanoprisms (parallelepiped structures) and sphere-like nanoparticles of MnO or CoxMn1−xO. e, Scanning TEM image. f–h, EDX mapping of Co (f), Mn (g) and Co plus Mn (h). For the nanoprism particles, a higher concentration of Co and a very low concentration of Mn was observed; these results, coupled with the high-resolution TEM images of the lattice fringes, suggest that such nanoprisms are composed of Co2C. For most of the sphere-like nanoparticles, both Co and Mn were observed, indicating that these particles are composed of CoMn composite oxide (CoxMn1−xOy). For some of the sphere-like nanoparticles, only Mn was observed and the concentration of Co was very low, suggesting that these particles are composed of MnO.

Extended Data Figure 6 TEM images of the CoMn catalyst at different reaction times.

a–c, Low-resolution TEM images at 2 h (a), 10 h (b) and 20 h (c). d–f, Corresponding high-resolution TEM images. For the samples removed at 2 h, it was hard to find Co2C nanoprisms; the shape of the Co2C seemed to be irregular. At 10 h, the Co2C nanostructure seemed to be nanoprism-like, with a parallepiped shape, and the lattice fringes suggested the exposed facet of (101) geometry, although the shape was not perfect. At 20 h, Co2C nanoprisms were found.

Extended Data Figure 7 TEM, XRD and ICP analyses of the effects of Na and Mn on different Co-based catalysts.

a–c, Low-resolution TEM images of spent CoMn-A (a), CoMn-Na (b) and Co3O4 (c). d–f, Corresponding high-resolution TEM images. g, XRD patterns of spent CoMn-A, CoMn-Na and Co3O4 catalysts. h, Elemental analysis of the fresh catalysts by ICP mass spectrometry. To produce CoMn-A, CoMn catalyst (Co/Mn = 2/1) was precipitated with (NH4)2CO3. To produce CoMn-Na, CoMn catalyst (Co/Mn = 2/1) was precipitated with (NH4)2CO3 and impregnated with about 0.4 wt% of Na using Na2CO3. CoMn was prepared by precipitating CoMn catalyst (Co/Mn = 2/1) with Na2CO3. Co3O4 was prepared by precipitation using Na2CO3. We found CoMn-A to include sphere-like, face-centred-cubic, metallic Co nanoparticles. We detected Co2C nanoprisms in CoMn-Na, while Co3O4 comprised larger Co2C sphere-like nanoparticles.

Extended Data Figure 8 Catalytic performance and product distribution of different catalysts.

a, Performance of different catalysts. b–d, Product plot (ln(Wn/n) versus n) for CoMn-A (b), CoMn-Na (c) and Co3O4 (d) catalysts. CoMn-A, CoMn-Na and Co3O4 were prepared as described in Extended Data Fig. 7. MnO2 was prepared by precipitation using Na2CO3. Reaction conditions: 1 bar, 250 °C, 2,000 ml h−1 gcat−1, H2/CO = 2. There was no detectable CO conversion by MnO2.

Extended Data Figure 9 DFT study on different surfaces.

a, Top views (upper panels) and side views (bottom panels) of different surfaces: from left to right, Co2C(101), Co2C(020), Co2C(111) and Co(0001). Blue, Co atom; grey, C atom. b, Energy profiles for CH4 formation on Co2C(101), Co2C(020), Co2C(111) and Co(0001) surfaces. The intermediate state of CH2 + 2H is chosen as the zero point for all of the energy profiles.

Rights and permissions

About this article

Cite this article

Zhong, L., Yu, F., An, Y. et al. Cobalt carbide nanoprisms for direct production of lower olefins from syngas. Nature 538, 84–87 (2016). https://doi.org/10.1038/nature19786

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature19786

This article is cited by

-

Efficient Syngas-to-Olefins Conversion via Kaolin Modified SAPO-34 Catalyst

Catalysis Letters (2024)

-

Boosting Fischer–Tropsch Synthesis via Tuning of N Dopants in TiO2@CN-Supported Ru Catalysts

Transactions of Tianjin University (2024)

-

Achieving simultaneously high conversion and high selectivity for light olefins directly producing from syngas

Science China Chemistry (2024)

-

Precise solid-phase synthesis of CoFe@FeOx nanoparticles for efficient polysulfide regulation in lithium/sodium-sulfur batteries

Nature Communications (2023)

-

Generation of oxide surface patches promoting H-spillover in Ru/(TiOx)MnO catalysts enables CO2 reduction to CO

Nature Catalysis (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.