Abstract

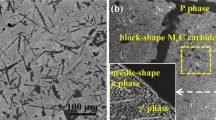

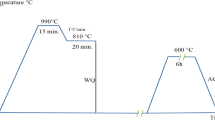

The tribological performance of Ti–29Nb–14Ta–4.5Zr alloy against Ti–6Al–4V ELI was investigated for the mild condition, emphasized on the superficial changes and changes underneath the wear track. The results of X-ray photoelectron spectroscopy indicated that TiO2, Nb2O, Ta2O and Zr2O oxides aggregated to form a protective tribo-layer, which effectively prevented further superficial damages. Development of fine-grain layer and the occurrence of phase transformation of β → α’’/ω were characterized as the main wear-induced evolution of the subsurface layer. The wear-induced transformation increases the hardenability of the subsurface layer, effectively support the worn surface and prevent premature cracking. These phenomenal evolutions were led to a simultaneous increase in the strength and ductility and subsequently wear loss reduction in comparison to the Ti64 ELI.

Graphic Abstract

Similar content being viewed by others

References

Y. Yang, Y. Zhu, M.M. Khonsari, H. Yang, Wear anisotropy of selective laser melted 316L stainless steel. Wear 428–429, 376–386 (2019)

Y.S. Zhang, Q.M. Wei, H.Z. Niu, Y.S. Li, C. Chen, Z.T. Yu, X.F. Bai, P.X. Zhang, Formation of nanocrystalline structure in tantalum by sliding friction treatment. Int. J. Refract. Metals Hard Mater. 45, 71–75 (2014)

Y.S. Zhang, H.Z. Niu, L.C. Zhang, X.F. Bai, X.M. Zhang, P.X. Zhang, Grain coarsening behavior in a nanocrystalline copper subjected to sliding friction. Mater. Lett. 123, 261–264 (2014)

D. Liu, M. Shen, Y. Tang, Y. Hu, L. Zhao, Effect of multipass friction stir processing on surface corrosion resistance and wear resistance of ZK60 alloy. Metals Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00268-5

H.Q. Sun, Y.N. Shi, M.X. Zhang, Wear behaviour of AZ91D magnesium alloy with a nanocrystalline surface layer. Surf. Coat. Technol. 202, 2859–2864 (2008)

G. Stachowiak, A.W. Batchelor, Engineering Tribology, 4th edn. (Elsevier, 2014). eBook ISBN: 9780123977762, Hardcover ISBN: 9780123970473, Paperback ISBN: 9780128100318. https://www.elsevier.com/books/engineering-tribology/stachowiak/978-0-12-397047-3

B. Bhushan, Modern Tribology Handbook, vol. 2, 1st edn. (CRS Press, 2000). ISBN: 9780849384035. https://www.crcpress.com/Modern-Tribology-Handbook-Two-Volume-Set/Bhushan/p/book/9780849384035

S. Sadeghpour, S.M. Abbasi, M. Morakabati, L.P. Karjalainen, D.A. Porter, Effect of cold rolling and subsequent annealing on grain refinement of a beta titanium alloy showing stress-induced martensitic transformation. Mater. Sci. Eng. A 731, 465–478 (2018)

W.J. Kim, S.J. Yoo, J.B. Lee, Microstructure and mechanical properties of pure Ti processed by high-ratio differential speed rolling at room temperature. Scr. Mater. 62, 451–454 (2010)

Y.S. Lee, M. Niinomi, M. Nakai, K. Narita, K. Cho, Predominant factor determining wear properties of β-type and (α + β)-type titanium alloys in metal-to-metal contact for biomedical applications. J. Mech. Behav. Biomed. Mater. 41, 208–220 (2015)

T. Yao, K. Du, H. Wang, Z. Huang, C. Li, L. Li, Y. Hao, R. Yang, H. Ye, In situ scanning and transmission electron microscopy investigation on plastic deformation in a metastable β titanium alloy. Acta Mater. 133, 21–29 (2017)

H. Zhan, G. Wang, D. Kent, M. Dargusch, The dynamic response of a metastable β Ti–Nb alloy to high strain rates at room and elevated temperatures. Acta Mater. 105, 104–113 (2016)

W.L. Wang, X.L. Wang, W. Mei, J. Sun, Role of grain size in tensile behavior in twinning-induced plasticity β Ti–20V–2Nb–2Zr alloy. Mater. Charact. 120, 263–267 (2016)

M. Ahmed, D. Wexler, G. Casillas, D.G. Savvakin, E.V. Pereloma, Strain rate dependence of deformation—induced transformation and twinning in a metastable titanium alloy. Acta Mater. 104, 190–200 (2016)

W. Chen, S. Cao, W. Kou, J. Zhang, Y. Wang, Y. Zha, Y. Pan, Q. Hub, Q. Sun, J. Sun, Origin of the ductile-to-brittle transition of metastable β-titanium alloys: self-hardening of ω-precipitates. Acta Mater. 170, 187–204 (2019)

F. Haftlang, A. Zarei-Hanzaki, H. Abedi, The wear induced crystallographic texture transition in Ti–29Nb–14Ta–4.5Zr alloy. Appl. Surf. Sci. 491, 360–373 (2019)

X. Tang, T. Ahmed, H.J. Rack, Phase transformations in Ti–Nb–Ta and Ti–Nb–Ta–Zr alloys. J. Mater. Sci. 35, 1805–1811 (2000)

W. Xu, X. Wu, M. Calin, M. Stoica, J. Eckert, K. Xia, Formation of an ultrafine-grained structure during equal-channel angular pressing of a β-titanium alloy with low phase stability. Scr. Mater. 60, 1012–1015 (2009)

F. Haftlang, A. Zarei Hanzaki, H.R. Abedi, D. Preisler, K. Bartha, The subsurface frictional hardening: a new approach to improve the high-speed wear performance of Ti–29Nb–14Ta–4.5Zr alloy against Ti–6Al–4V extra-low interstitial. Wear 422–423, 137–150 (2019)

M.M. Dewidar, H.C. Yoon, J.K. Lim, Mechanical properties of metals for biomedical applications using powder metallurgy process: a review. Metals Mater. Int. 12, 193 (2006)

R. Buscher, A. Fischer, The pathways of dynamic recrystallization in all-metal hip joints. Wear 259, 887–897 (2005)

NIST X-ray Photoelectron Spectroscopy Database, NIST Standard Reference Database Number 20, National Institute of Standards and Technology, Gaithersburg MD, 20899 (2000). https://doi.org/10.18434/T4T88K

J.M. Calderon Moreno, M. Popa, S. Ivanescu, C. Vasilescu, S.I. Drob, E.I. Neacsu, M.V. Popa, Microstructure, mechanical properties, and corrosion resistance of Ti–20Zr alloy in undoped and NaF doped artificial saliva. Metals Mater. Int. 20, 177–187 (2014)

C.W. Chan, S. Lee, G. Smith, G. Sarri, C.H. Ng, A. Sharba, H.-C. Man, Enhancement of wear and corrosion resistance of beta titanium alloy by laser gas alloying with nitrogen. Appl. Surf. Sci. 367, 80–90 (2016)

J.M. Cordeiro, B.E. Nagay, A.L.R. Ribeiro, N.C. Cruz, E.C. Rangel, L.M.G. Fais, L.G. Vaz, V.A.R. Barão, Functionalization of an experimental Ti–Nb–Zr–Ta alloy with a biomimetic coating produced by plasma electrolytic oxidation. J. Alloys Compd. 770, 1038–1048 (2019)

A. Sotniczuk, H.A. Garbacz, D. Kuczynska-Zemła, P. Kwasniak, M. Thomas, Corrosion behavior of Ti–29Nb–13Ta–4.6Zr and commercially pure Ti under simulated inflammatory conditions e comparative effect of grain refinement and non-toxic β phase stabilizers. Electrochim. Acta 312, 369–379 (2019)

W.Y. Guo, J. Sun, J.S. Wu, Electrochemical and XPS studies of corrosion behavior of Ti–23Nb–0.7Ta–2Zr–O alloy in Ringer’s solution. Mater. Chem. Phys. 113, 816–820 (2009)

Y. Xu, Y. Xiao, D. Yi, H. Liu, J. Wen, Corrosion behavior of Ti–Nb–Ta–Zr–Fe alloy for biomedical applications in Ringer’s solution. Trans. Nonferrous Metal. Soc. 25, 2556–2563 (2015)

S.F. Ren, J.H. Meng, J.B. Wang, J.J. Lu, S.R. Yang, Tribo-corrosion behaviors of Ti3SiC2/Si3N4 tribo-pair in hydrochloric acid and sodium hydroxide solutions. Wear 275, 8–14 (2012)

A. Gutierrez, M.F. Lopez, J.A. Jimenez, C. Morant, F. Paszti, A. Climent, Surface characterization of the oxide layer grown on Ti–Nb–Zr and Ti–Nb–Al alloys. Surf. Interface Anal. 36, 977–980 (2004)

M.T. Mohamed, Z.A. Khan, M. Geetha, Effect of thermo-mechanical processing on microstructure and electrochemical behavior of Ti–Nb–Zr–V new metastableβ titanium biomedical alloy. Trans. Nonferrous Metals Soc. China 25, 759–769 (2015)

C. Yin, Y. Liang, Y. Jiang, M. Yang, S. Long, Formation of nano-laminated structures in a dry sliding wear-induced layer under different wear mechanisms of 20CrNi2Mo steel. Appl. Surf. Sci. 423, 305–313 (2017)

N. Kamikawa, X. Huang, N. Tsuji, N. Hansen, Strengthening mechanisms in nanostructured high-purity aluminum deformed to high strain and annealed. Acta Mater. 57, 4198–4208 (2009)

J. Gao, Y. Huang, D. Guan, A.J. Knowles, L. Ma, D. Dye, W.M. Rainforth, Deformation mechanisms in a metastable beta titanium twinning induced plasticity alloy with high yield strength and high strain hardening rate. Acta Mater. 152, 301–314 (2018)

J.W. Won, T. Lee, S.G. Hong, Y. Lee, J.H. Lee, C.S. Lee, Role of deformation twins in static recrystallization kinetics of high-purity alpha titanium. Metals Mater. Int. 22, 1041–1048 (2016)

M.J. Lai, T. Li, D. Raabe, ω Phase acts as a switch between dislocation channeling and joint twinning- and transformation-induced plasticity in a metastable β titanium alloy. Acta Mater. 151, 67–77 (2018)

T. Lee, M. Nakai, M. Niinomi, C.H. Park, C.S. Lee, Phase transformation and its effect on mechanical characteristics in warm-deformed Ti–29Nb–13Ta–4.6Zr alloy. Metals Mater. Int. 21, 202–207 (2015)

J.F. Archard, Contact and rubbing of flat surfaces. J. Appl. Phys. 24, 981–988 (1953)

J.H. Jang, B.D. Joo, J.H. Lee, Y.H. Moon, Effect of hardness of the piston ring coating on the wear characteristics of rubbing surfaces. Metals Mater. Int. 15, 903–908 (2009)

W.F. Smith, Structure and Properties of Engineering Alloys (McGraw-Hill, New York, 1981)

T. Ahmed, H.J. Rack, Phase transformations during cooling in α + β titanium alloys. Mater. Sci. Eng. A 243, 206–211 (1998)

I. Cvijović-Alagić, Z. Cvijović, S. Mitrović, V. Panić, M. Rakin, Wear and corrosion behaviour of Ti–13Nb–13Zr and Ti–6Al–4V alloys in simulated physiological solution. Corros. Sci. 53, 796–808 (2011)

Acknowledgements

This work was partly supported by the Ministry of Education, Youth and Sport of the Czech Republic, Program NPU1, Project No. LO1207. Deakin University’s Advanced Characterization Facility is acknowledged for use of the electron microscopy instruments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Haftlang, F., Zarei-Hanzaki, A., Abedi, H.R. et al. Outstanding Mild Wear Performance of Ti–29Nb–14Ta–4.5Zr Alloy Through Subsurface Grain Refinement and Supporting Effect of Transformation Induced Plasticity. Met. Mater. Int. 26, 467–476 (2020). https://doi.org/10.1007/s12540-019-00344-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00344-w