Abstract

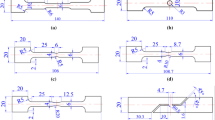

This paper is concerned with modeling of fracture strains of DP780 using a newly proposed micro-mechanism-motivated ductile fracture criterion (Lou et al., 2012) and its application to predict limit dome heights (LDH) for nine hemispherical punch-stretch tests. Dog-bone specimens are tested to characterize strain hardening behavior. Five arc-shaped specimens and four square-shaped specimens are drawn until fracture to construct a fracture forming limit diagram (FFLD) using circle grid analysis. Fracture strains are approximated from constructed FFLD in uniaxial, plane strain and balanced biaxial tension. The approximated fracture strains are employed to calculate material constants of the proposed criterion as well as six conventional criteria. FFLDs predicted by these criteria are compared with experimental results. The comparison demonstrates that only the proposed criterion describes FFLD perfectly from uniaxial tension to balanced biaxial tension. All criteria are implemented into ABAQUS/Explicit to predict LDHs of punch-stretch tests. Numerical results indicate that LDHs are severely underestimated for the square-shaped specimens by conventional criteria while the proposed criterion predicts LDHs with good agreement for nine tests with strain paths between uniaxial tension and balanced biaxial tension. Thus, the proposed criterion is recommended to access formability from uniaxial tension to balanced biaxial tension.

Similar content being viewed by others

References

M. G. Cockcroft and D. J. Latham, J. Inst. Met. 96, 33 (1968).

J. R. Rice and D. M. Tracey, J. Mech. Phys. Solids 17, 201 (1969).

P. Brozzo, B. DeLuca, and R. Rendina, Proc. 7th Bi. Conf. IDDRG, Amsterdam (1972).

S. I. Oh, C. C. Chen, and S. Kobayashi, Trans. ASME, J. Eng. Ind. 101, 36 (1979).

M. Oyane, T. Sato, K. Okimoto, and S. Shima, J. Mech. Work. Technol. 4, 65 (1980).

S. E. Clift, P. Hartley, C. E. N. Sturgess, and G. W. Rowe, Int. J. Mech. Sci. 32, 1 (1990).

H. N. Han and K.-H. Kim, J. Mater. Process. Technol. 142, 231 (2003).

Y. K. Ko, J. S. Lee, H. Huh, H. K. Kim, and S.-H. Park, J. Mater. Process. Technol. 187–188, 358 (2007).

H. Takuda, K. Mori, H. Fujimoto, and N. Hatta, J. Mater. Process. Technol. 60, 291 (1996).

H. Takuda, K. Mori, and N. Hatta, J. Mater. Process. Technol. 95, 116 (1999).

M. Jain, J. Allin, and D. J. Lloyd, Int. J. Mech. Sci. 41, 1273 (1999).

L. P. Lei, B. S. Kang, and S. J. Kang, J. Mater. Process. Technol. 113, 673 (2001).

C. L. Chow and M. Jie, Int. J. Mech. Sci. 46, 99 (2004).

Y. B. Bao and T. Wierzbicki, J. Eng. Mater. Tech. ASME 126, 314 (2004).

F. Ozturk and D. Y. Lee, J. Mater. Process. Technol. 147, 397 (2004).

S.-T. Oh, H.-J. Chang, K.H. Oh, and H. N. Han, Met. Mater. Int. 12, 121 (2006).

C. Vallellano, D. Morales, and F. J. Garchi-Lomas, Mater. Manuf. Process. 23, 303 (2008).

J. S. Chen, X. B. Zhou, and J. Chen, J. Mater. Process. Technol. 210, 315 (2010).

Y. S. Lou, H. Huh, S. J. Lim, and K. H. Pack, Int. J. Solids Struct. 49, 3605 (2012).

Y. S. Lou and H. Huh, Int. J. Solids Struct. 50, 447 (2013).

Y. S. Lou and H. Huh, J. Mater. Process. Technol. (2013) (doi: 10.1016/j.jmatprotec.2013.03.001.)

Y. S. Lou, and H. Huh, Int. J. Solids Struct. 50, 447 (2013).

S. B. Kim, H. Huh, H. H. Bok, and M. B. Moon, J. Mater. Process. Technol. 211, 851, (2011).

M. Luo and T. Wierzbicki, Int. J. Solids Struct. 47, 3084 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lou, Y., Lim, S.J. & Huh, H. Prediction of fracture forming limit for DP780 steel sheet. Met. Mater. Int. 19, 697–705 (2013). https://doi.org/10.1007/s12540-013-4009-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-4009-3