Abstract

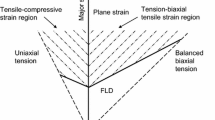

A strain-based forming limit criterion is widely used in sheet-metal forming industry to predict necking. However, this criterion is usually valid when the strain path is linear throughout the deformation process [1]. Strain path in incremental sheet forming is often found to be severely nonlinear throughout the deformation history. Therefore, the practice of using a strain-based forming limit criterion often leads to erroneous assessments of formability and failure prediction. On the other hands, stress-based forming limit is insensitive against any changes in the strain path and hence it is first used to model the necking limit in incremental sheet forming. The stress-based forming limit is also combined with the fracture limit based on maximum shear stress criterion to show necking and fracture together. A derivation for a general mapping method from strain-based FLC to stress-based FLC using a non-quadratic yield function has been made. Simulation model is evaluated for a single point incremental forming using AA 6022-T43, and checked the accuracy against experiments. By using the path-independent necking and fracture limits, it is able to explain the deformation mechanism successfully in incremental sheet forming. The proposed model has given a good scientific basis for the development of ISF under nonlinear strain path and its usability over conventional sheet forming process as well.

Similar content being viewed by others

References

Stoughton TB, Yoon JW (2012) Path independent forming limits in strain and stress spaces. Int J Solids Structure 49:3616–3625

Kleemola HJ, Pelkkikangas MT (1977) Effect of predeformation and strain path on the forming limits of steel, copper, and brass. Sheet Metal Indust 63:591–599

Stoughton TB (2000) General forming limit criterion for sheet metal forming. Int J Mech Sci 42:1–27

Stoughton TB, Yoon JW (2005) Sheet metal formability analysis for anisotropic materials under non-proportional loading. Int J Mech Sci 47:1972–2002

T. Kuwabara, K. Yoshida, K. Narihara, S. Takahashi, Forming limits of aluminum alloy tubes under axial load and internal pressure. Proceedings of Plasticity’03, NEAT Press (2003) 388-390

Stoughton TB, Yoon JW (2011) A new approach for failure criterion for sheet metals. Int J Plast 27:440–459

J.W. Yoon, F. Barlat, R.E. Dick, Sheet metal forming simulation for aluminum alloy sheet, SAE 2000, Michigan, USA, 2000, pp.66–72

Barlat F, Brem JC, Yoon JW, Chung K, Dick RE, Lege DJ, Pourboghrat F, Choi SH, Chu E (2003) Plane stress yield function for aluminum alloy sheets. Int J Plastic 19:1297–1319

M.Z. Haque, J.W. Yoon, Stress-based predictions of formability and failure in incremental sheet forming, NUMISHEET 2014 : Part B General Papers edited by J.W. Yoon, B. Rolfe, J.H. Beynon, P. Hodgson, AIP Proceeding, Vol. 1567, pp. 816–819 (2013)

Życzkowski M (1981) Combined loadings in the theory of plasticity. Polish Scientific Publisher, Warsaw

Hosford WF (1972) A generalized isotropic yield criterion. J Appl Mech Trans ASME 39:607–609

Yoon JW, Barlat F, Dick RE, Chung K, Kang TJ (2004) Plane stress yield function for aluminum alloy sheet-part II : FE formulation and its implementation. Int J Plastic 20:495–522

Barlat F, Aretz H, Yoon JW, Karabin ME, Brem JC, Dick RE (2005) Linear transformation-based anisotropic yield functions. Int J Plastic 21:1009–1039

Yoon JW, Barlat F, Dick RE, Karabin ME (2006) Prediction of six or eight ears in a drawn cup based on a new anisotropic yield function. Int J Plastic 22:174–193

Graf A, Hosford WF (1993) Calculations of forming limit diagrams for changing strain paths. Met Trans A24:2497–2501

S.H. Hong, J.W. Yoon, D.S. Han, Anisotropic material modeling for automotive sheet alloys. NUMISHEET2008 edited by P.Hora, September 1–5, Interlaken, Switzerland, 2008, p. 105–110

B.M. Esteban, T.W. Paul, B. Christy, Framework for integrated robust and reliability optimization of sheet-metal stamping process, in annual progress report for lightweighting materials 2007 :2. Automotive Metals—Wrought 2008, US Department of Energy Office of Vehicle Technologies, 2008, p. 24–25

Acknowledgments

This work is partially supported by a FCT project of PTDC/EME-TME/ 109119/2008 in Portugal. The authors are very thankful for this support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haque, M.Z., Yoon, J.W. Stress based prediction of formability and failure in incremental sheet forming. Int J Mater Form 9, 413–421 (2016). https://doi.org/10.1007/s12289-015-1237-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-015-1237-8