Abstract

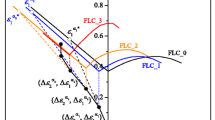

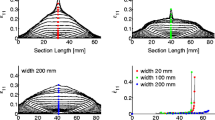

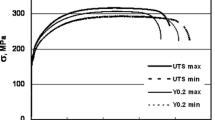

Many practitioners of the metal forming community remain faithful to the idea that strain metrics are useful for formability assessment. However, it is only valid when deformation occurs along linear strain paths. Current simulations of multi-stage sheet forming processes for rigid-packaging and automotive components result in higher rejection rates due to the inaccuracy of forming and fracture limit models. In this work, we establish a new approach considering path-independency in forming limits based on the stress-based forming limit and polar EPS (Effective Plastic Strain) diagram which appear to be an effective solution for nonlinear effects. The related theory has been implemented into a user material model in commercial software.

Similar content being viewed by others

References

Graf A, Hosford WF (1993) Calculations of forming limit diagrams for changing strain paths. Metall Trans A A24:2497–2501

Kleemola HJ, Pelkkikangas MT (1977) Effect of predeformation and strain path on the forming limits of steel, copper, and brass. Sheet Met Ind 63:591–599

Arrieux R, Bedrin C, Boivin M (1982) Determination of an intrinsic forming limit stress diagram for isotropic metals sheets. Proc. Congress International Deep Drawing Research Group, S. Margherita Ligure, Italy, May 1982, Working Group Volume, pp. 61–72

Stoughton TB (2000) General forming limit criterion for sheet metal forming. Int J Mech Sci 42:1–27

Stoughton TB, Yoon JW (2005) Sheet metal formability analysis for anisotropic materials under non-proportional loading. Int J Mech Sci 47:1972–2002

Kuwabara T, Yoshida K, Narihara K, Takahashi S (2003) Forming limits of aluminum alloy tubes under axial load and internal pressure. Proceedings of Plasticity’03, NEAT Press, pp. 388–390

Volk W, Hora P, (2010) New algorithm for a robust user-independent evaluation of beginning instability for the experimental FLC determination. Int J Mater Form 1–8

Merklein M, Kuppert A, Geiger M (2010) Time dependent determination of forming limit diagrams. Ann CIRP 59–1:295–298

Hora P, Tong L (2006) Numerical Prediction of FLC using the Enhanced Modified Maximum Force Criterion (EMMFC), Proc FLC Zurich 31–36

Isik K, Silva MB, Tekkaya AE, Martins PAF (2014) Formability limits by fracture in sheet metal forming. J Mater Process Technol 214:1557–1565

Hooputra H, Gese H, Dell H, Werner H (2004) A comprehensive failure model for crashworthiness simulation of aluminium extrusions. Int J Crashworthiness 9:449–464

Volk W, Suh J (2013) Prediction of formability for non-linear deformation history using Generalized Forming Limit Concept (GFLC), NUMISHEET 2014: Part B General Papers edited by J.W. Yoon, B. Rolfe, J.H. Beynon, P. Hodgson, AIP Proceeding Vol. 1567, pp. 556–561

Stoughton TB, Yoon JW (2012) Path independent forming limits in strain and stress spaces. Int J Solids Struct 49:3616–3625

Hosford WF (1993) Metal forming: mechanics and metallurgy, 2nd edn. PTR Prentice-Hall Inc., New Jersey, ISBN 0-13-556135-3

Hill R (1948) A theory of the yielding and plastic flow of anisotropic metals. Proc R Soc Lond A 193:281–297

Zeng D, Chappuis L, Xia ZC, Zhu X (2008) A path independent forming limit criterion for sheet metal forming simulations, SAE 2008-01-1445

Acknowledgments

This work is partially supported by a FCT project of PTDC/EME-TME/ 109119/2008 in Portugal. The authors are very thankful for this support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dick, R.E., Yoon, J.W. & Stoughton, T.B. Path-independent forming limit models for multi-stage forming processes. Int J Mater Form 9, 327–337 (2016). https://doi.org/10.1007/s12289-015-1220-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-015-1220-4