Abstract

The buckwheat flour was studied as a potential healthy ingredient for improving the nutritional and technological quality of gluten-free bread. The effect of exchange of gluten-free formulation mass by buckwheat flour in 10, 20, 30 and 40 % was investigated. The increase in loaf specific volume with rising buckwheat flour addition was observed. Compared with the control sample, decrease in whiteness and increase in redness and yellowness of crumb were noticed. The rising amount of buckwheat flour in gluten-free bread formulation caused a decrease in crumb hardness during storage. This was in agreement with the decrease in starch gelatinisation enthalpy with the increasing amount of buckwheat flour in gluten-free formula in comparison with the control sample. Buckwheat flour could be incorporated into gluten-free formula and have a positive influence on bread texture and delaying its staling.

Similar content being viewed by others

Introduction

Recent epidemiologic studies have shown that the prevalence of celiac disease or non-typical celiac disease, or allergic reaction/intolerances to gluten has been significantly underestimated (Gallagher et al. 2004). These kinds of diseases are connected with life-long intolerance to gliadin fraction of wheat and prolamins of rye (secalins), barley (hordeins) and possibly oats (avenins) (Vader et al. 2003). Different substances are added to gluten-free formula, which could mimic the viscoelastic properties of gluten and result in the improvement of the structure, mouthfeel, acceptability and shelf-life of gluten-free products (Gallagher et al. 2003; Gujral et al. 2003; Ahlborn et al. 2005). A diet based on gluten-free products is characterised by a low content of some nutritional components such as proteins and mineral, as well as non-nutritional but physiologically important components like dietary fibre. Therefore, searching for components supplementing gluten-free products, which will provoke an increase in the content of the nutritional and dietary components, is necessary. Buckwheat flour is applied as a food additive or in the production of such foodstuffs as pancakes, pastas and noodles (Handoyo et al. 2006). Buckwheat proteins have high biological value due to the well-balanced amino acid composition, although their digestibility is relatively low (Kato et al. 2001; Tomotake et al. 2006). Buckwheat flour can be a valuable ingredient in diets or food products for coeliac patients due to a very low content of α-gliadin in the grains. Furthermore, this product is rich in thiamine (vitamin B1), riboflavin (vitamin B2) and pyridoxine (vitamin B6) (Fabjan et al. 2003). It is also a significant source of microelements, including: Zn, Cu, Mn and Se (Stibilj et al. 2004), as well as of macroelements, including: K, Na, Ca and Mg (Wei et al. 2003). With typically 80 % unsaturated fatty acids and more than 40 % polyunsaturated essential fatty acid–linoleic acid, buckwheat is nutritionally superior in fatty acid composition to cereal grains (Steadman et al. 2001). Additionally, buckwheat grains are a rich source of dietary fibre, including its soluble fraction, being of significance in a diet of patients suffering from obesity or type II diabetes (Brennan 2005). Their potential antioxidant activity is also of significance to the dietary value because of a high content of rutin, catechins and polyphenols (Oomah and Mazza 1996; Wanatabe 1998). Buckwheat is used as a supplement of food which can provide beneficial health effect and prevent food from oxidation during processing. Utilisation of buckwheat as a component of wheat bread is known and documented (Fujarczuk and Żmijewski 2009; Lin et al. 2009); Fessas et al. (2008) investigated the role of the main components of buckwheat flour on wheat dough thermal properties. Also, thermal properties of buckwheat starch and proteins have been analysed (Li et al. 1997; Tang 2007), but still there are some technological properties and potentialities of this pseudocereal which have not been analysed and described.

The objective of the present investigation was to study the effect of replacing corn starch from the gluten-free formulations by different amounts of buckwheat flour due to its health-promoting properties for human nutrition and to study the effect on the gluten-free bread quality and staling.

Materials and Methods

Materials

Commercial corn starch (AGROTRADE, Warsaw, Poland), potato starch (Cargill Sp. z o.o., Poland) and pectin (E 440(i) from ZPOW PEKTOWIN, Jasło, Poland) were used for gluten-free formulation. Commercial Polish dehulled buckwheat grains purchased from a local shop (Olsztyn, Poland) were milled and sieved (ϕ 0.4 mm) in order to obtain flour. Fresh yeast (Saccharomyces cerevisiae; Lesaffre Poland, Poland) was used as starter for the bread making process.

Bread Making Process

The basic formula of gluten-free bread was presented in Table 1 and was made according to the procedure described in Polish patent specification P 386253 (Wronkowska et al. 2008). The amount of added water was 80 g for 100 g of gluten-free formulation. The mixture was blended with a planetary rotation of mixing within a five-speed mixer (Kitchen Aid, USA) for 12 min. The dough was proofed at 35–40 °C for 40 min and baked at 215 °C for 25–35 min. The baking tests were carried out in an electric oven with an incorporated proofing chamber (ZBPP, Bydgoszcz, Poland).

The buckwheat flour substituted 0, 10, 20, 30 and 40 % w/w of gluten-free formulas basis, and corn starch was replaced by buckwheat flour. The following sample abbreviations were used: control, 10 % BF, 20 % BF, 30 % BF and 40 % BF.

Bread Quality

Loaf volume was determined using the standard millet displacement method (AACC 2000), and crumb porosity was analysed according to Dallmann’s pore table (Dallmann 1958).

Digital image analysis was used to measure bread crumb grain. Images were previously squared at 90 pixels per cm2 with a flatbed scanner (Epson Perfection V200 Photo) supported by Epson Creativity Suite Software. A single 20 ×20-mm square field of view from four central slices (10 mm thick) was used, thereby yielding four digital images per treatment. Data were processed using the SigmaScan Pro image analysis software (version 5.0.0, SPSS Inc., USA). The chosen crumb grain features were: mean cell area (square millimetre), number of cells per square centimetre, and cell area/total area (square centimetre/square centimetre) (Sanz-Penella et al. 2009).

Texture properties of crumb were measured using compression device of Instron 4301 universal testing machine (Canton, MA, USA). The crumb samples of gluten-free bread (20 × 20 × 20 mm) were compressed until 50 % strain at crosshead speed of 20 mm/min (Mohan and Skiner 1986). Hardness was the parameter describing the resistance for compression of bread crumbs of freshly baked loaves (2 h after baking). Staling was studied by measuring firmness over a storage period of 3 days at ambient temperature in polyethylene bags (24, 48 and 72 h).

The instrumental measurement of the bread crumb and crust colour was carried out with a ColorFlex (HunterLab, USA), and the results were expressed in accordance with the CIELab system with reference to illuminant D65 and a visual angle of 10°. The measurements were performed through a 3-cm-diameter diaphragm containing an optical glass. The parameters determined were: L* [L* = 0 (black) and L* = 100 (white)], a* (–a* = greenness and +a* = redness) and b* (–b* = blueness and +b* = yellowness). For measuring the crumb colour, bread was cut into two halves, and four replicates were made for each gluten-free bread formulation. The browning index (BI) of the crust was calculated as follows (Palou et al. 1999):

where,

Differential Scanning Calorimetry

Samples of dough were prepared as described for gluten-free bread making process section (without yeast and oil). Differential scanning calorimetry (DSC) measurements were made with a DSC-7 (Perkin-Elmer, USA). Dough samples of 20–30 mg were weighed in stainless steel pans (PE 0319-0218). To simulate the temperature profile in the centre of the bread crumb during baking, calorimeter scan conditions were used according to the methodology described by León et al. (1997) with slight modifications (Sanz-Penella et al. 2010). Samples were kept at 30 °C for 1 min, then heated from 30 to 100 °C at the rate 11.7 °C/min, and kept at this temperature until 12 min and cooled to 30 °C. To analyse starch retrogradation, heated-cooled pans were stored at room temperature for 2, 4, 6, 17, 24, 48 and 72 h, and heated again in the calorimeter from 30 to 100 °C, at 10 °C/min rate (Sanz-Penella et al. 2010). An empty pan was used as a reference, and three replicates of all samples were analysed. The parameters recorded were onset temperature (T o), peak temperature (T p) and conclusion temperature (T c) of amylopectin retrogradation. Straight lines were drawn between T o and T c, and the enthalpies associated with starch gelatinisation (ΔH r ) were calculated as the area enclosed by the straight line and endotherm curve. The enthalpies were expressed in Joules per gram of starch.

Statistical Analysis

The measurements were performed in at least five repetitions for each of five loaves obtained from two separate bread making processes for every gluten-free formulation. The reported data are the mean results for each formulation with the standard deviation.

The results were analysed using the statistical program Statgraphics Centurion XV (StatPoint Inc., VA, USA). Fisher’s least-significant differences test was used to define differences between means at the 5 % significance level (p < 0.05). Data obtained for hardness and enthalpies of starch gelatinisation were analysed using two-way ANOVA with the aid of Statistica 6.0 for Windows (StatSoft Corp, Krakow, Poland). Multiple comparisons of the means were performed using Duncan’s multiple range test at 5 % probability.

Results and Discussion

The effect of the corn starch substitution by buckwheat flour in gluten-free formulation on technological quality parameters of bread loaves was analysed (Table 2). The inclusion of buckwheat flour did not influence significantly the loaf moisture content. However, the loaf specific volume was modified significantly by inclusion and increasing amount of buckwheat flour from 2.97 to 3.28 mL/g. The consumers often get attracted by bread loaf with higher volume, so the reduction of loaf size during the baking process is undesirable. The improvement of the specific volume of gluten-free bread from rice flour by the inclusion of gums, pectin, carboxymethylcellulose, agarose, xanthan or oat β-glucan was analysed previously (Kang et al. 1997; Lazaridou et al. 2007); Sabanis et al. (2009) found that addition of insoluble fibres to gluten-free formulations significantly increased the bread volume. However, ingredients as starch isolated from unprocessed or autoclaved bean seeds incorporated to the gluten-free bread did not influence significantly this parameter (Krupa et al. 2010). Christa et al. (2009) found that the water-binding capacity of starch isolated from buckwheat grains (1.5 g water/g d.m) was higher than results obtained for wheat or potato starches (0.65 and 0.73 g water/g d.m, respectively). Kereliuk and Sosulski (1996) showed that the water-binding capacity of the three different corn starches was about 1 g water/g d.m. The differences in water-binding capacity of buckwheat and corn or potato starches could explain the significant increase in the loaf specific volume which was observed after the inclusion and increasing amount of buckwheat flour. The buckwheat proteins are the next component which could influence the improvement of specific volume of gluten-free bread.

Porosity of gluten-free bread crumb defined by the image analysis showed significant differences (p < 0.05) with the inclusion of buckwheat flour (Table 2, Fig. 1). A significant decrease in the mean cell area of the crumb of 10 % BF bread compared with the control sample was noticed (Table 2), whereas the highest mean cell area of the crumb (not statistically significant) was found for gluten-free bread with 40 % of buckwheat flour. The number of crumb cells per square centimetre was significantly higher for all the investigated gluten-free breads compared to the control sample. The gluten matrix is a major determinant of the important properties of dough because of its gas-holding ability. The formulation without gluten can only retain gas if another gel replaces gluten, being important that the ingredients form a continuous phase for stabilizing gas cells (Gallagher et al. 2004; Sabanis et al. 2009). In this study, the gluten-free breads with increasing amount of buckwheat flour showed better crumb structure than the control bread (Fig. 1). Crumb porosity analysed according to Dallmann’s pore table showed that the control sample was characterised by 4 points, whereas for the experimental gluten-free breads, it was 7 points (10 % BF) and 8 points (20–40 %BF). The crumb structure of breads depends on its species, and for rye bread, it is about 5–7 points, and for wheat breads, it is about 7–8 points. Fujarczuk and Żmijewski (2009) found an improvement of crumb porosity, analysed according Dallmann’s pore table, with the increase in the amount of buckwheat bran added to wheat flour.

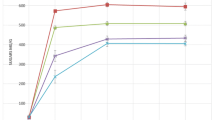

On the other hand, another important property of bakery products is the crumb hardness, which is related to the force required to compress the food between the molars since it is strongly related to the freshness perception of consumers (Giannou and Tzia 2007). The hardness of fresh gluten-free bread (2 h after baking) decreased with the increasing amount of buckwheat flour in the formulation, from 2.3 (control) to 1.1 Pa (40 % BF), mainly due to the increased volume of the loaves (Table 2).

The changes of hardness of gluten-free bread crumb during a 72-h storage in polyethylene bags at room temperature are shown in Table 2. As was expected, the crumb hardness increased as a consequence of storage, which is a common phenomenon for baking gluten-free products (Gallagher et al. 2004). The interesting observation was made for the gluten-free breads with the amount of buckwheat higher than 10 %. The hardness of each investigated formulation increased significantly during the first 24 h of storage, but for the next 48 h, no statistically significant changes were noticed. However, it was found that with the increasing amount of buckwheat flour, crumb hardness decreased during the analysis compared to the control sample.

The variation in the crumb and crust colour parameters of the gluten-free breads due to the addition of buckwheat flour are summarized in Table 2 and shown in Fig. 1. The crust colour parameters showed a decrease in whiteness and a statistically significant increase in browning index, which is connected with the increasing amount of buckwheat flour compared to the control sample. The rising buckwheat flour level in gluten-free formula caused the statistically significant (p < 0.05) decrease in whiteness and increase in redness and yellowness of crumb compared to the control sample. Together with texture and aroma, colour is an important property of baked products. Gluten-free breads are usually characterised by lighter colour than wheat breads; due to this, the darkening of bread in general is desirable. In respect of colour parameter (L*, a* and b*), the gluten-free breads obtained in this study nearly resemble whole wheat bread (Fig. 1). The L* value for a whole wheat bread crumb was 56, whereas for bread made from the whole wheat and wheat flour (50:50), it was 61 as presented by Sanz-Penella et al. (2009). Lin et al. (2009) found that the crumb of wheat bread was lighter than the crumb of buckwheat-enhanced wheat bread (L* values about 77 and about 68, respectively); also, a* and b* values were much higher in the case of wheat bread with buckwheat (3 and 21, respectively). The crust colour is one of the critical factors in the bread baking process. The yellow-gold colour formation is often called browning. This transformation is connected with chemical reactions producing coloured compounds during bread baking, especially caramelisation and Maillard reactions. The browning index represents the purity of brown colour and is reported as an important parameter in processes where enzymatic or nonenzymatic browning takes place. In this study, the increasing amount of buckwheat flour caused the statistically significant increase in crust browning index.

Amylopectin retrogradation is one of the most important factors responsible for bread staling (León et al. 1997). This becomes even more evident in gluten-free breads, which are mainly based on starch. The DSC can measure the enthalpy associated to amylopectin recrystallization, and provides a way of monitoring the progressive magnitude of staling endotherm (Biliaderis 1992). The decrease in enthalpy of starch gelatinisation (ΔH) with the increasing amount of buckwheat flour in gluten-free formula was found in comparison with the control sample (Table 3). This finding is in agreement with the decrease in hardness of gluten-free breads with higher amount of buckwheat flour during the 72-h storage in polyethylene bags at room temperature (Table 2). Relkin (2005) found that thermal behaviour of wheat dough with the addition of buckwheat flour could be explained by two different properties of starch granules (wheat and buckwheat starch), also by molecular interactions between proteins and polysaccharides in buckwheat flour and by technological processing used for baking. In the case of our study, three different types of starch: corn, potato and buckwheat, and also buckwheat protein and sugar were the factors which could influence the thermal properties of the investigated gluten-free products. Starches from different botanical sources are diversified in their composition and exhibit different transition temperatures and enthalpies of gelatinisation (Singh et al. 2007). Li et al. (1997) found that enthalpy of gelatinization of the buckwheat starches (normal and tartary) was generally similar and ranged from 9.1 to 11 J/g. According to Singh et al. (2003), enthalpy of gelatinisation of the starches from different botanical sources was: 12.5–17.9 J/g for potato starch, 12–14 J/g for corn starch, 8.2–13 J/g for rice starch and 9–17.9 J/g for wheat starch. When heat was applied to a food system containing starch, the initial temperature of gelatinisation of the starch and the temperature of the peak increased, meanwhile the gelatinisation enthalpy decreased (Abd Elgadir et al. 2009). During bread baking, starch granules swell and gelatinise. The conditions in which these phenomena occur determine the quality of the bread. Sikora et al. (2010) presented that values of gelatinisation temperature of gluten-free dough were higher as compared to gluten-containing dough, which was explained by the sucrose content in the gluten-free dough recipes. This is consistent with the papers of Evans and Haisman (1982) and Spies and Hoseney (1982), who claimed that sugars added to starch mixtures increased the gelatinisation temperature. The results obtained in the present study showed that the amount of buckwheat flour added to the gluten-free dough did not have a direct influence on the values of enthalpies of starch gelatinisation. The increase in the enthalpy was observed in the case of the gluten-free dough with the buckwheat flour supplementation up to 30 %. Forty percent exchange of corn starch into buckwheat flour caused the decrease in this parameter. This phenomenon may be caused by different types of starches existing in the gluten-free formulas and by the influence of the buckwheat proteins. Furthermore, with the increasing amount of buckwheat flour, the content of corn starch decreased. The changes in the proportion between the buckwheat and corn starches may also have an influence on the thermal properties of the investigated gluten-free products.

Zhou et al. (2009) study the effect of water content on the thermal behaviour of buckwheat flour and starch. They found that both temperature and enthalpy values increased with the increase in water content. For measuring the retrogradation of buckwheat flour, the samples were kept for 8 weeks. The retrogradation onset temperatures appeared much lower than the former corresponded gelatinisation temperatures. They explained that is probably due to the partial crystallization of amylase.

Summary

The gluten-free bread enriched by buckwheat flour investigated in this study had a significantly higher loaf volume. The crumb colour of experimental gluten-free breads was darker than the control sample, which might be noticeable to attract consumer’s attention. Delay in staling of buckwheat-enhanced gluten-free bread was observed. The present study proved the positive influence of buckwheat flour on gluten-free bread technological parameters.

References

AACC. (2000). Approved methods of the American Association of Cereal Chemists (10th ed.). St. Paul: AACC.

Abd Elgadir, M., Bakar, J., Zaidul, I. S. M., Abdul Rahman, R., Abbas, K. A., Hasim, D. M., & Karim, R. (2009). Thermal behaviour of selected starches in presence of other food ingredients studied by differential scanning calorimetry (DSC)—review. Comprehensive Reviews in Food Science and Food Safety, 8, 195–201.

Ahlborn, G. J., Pike, O. A., Hendrix, S. B., Hess, W. M., & Huber, C. S. (2005). Sensory, mechanical, and microscopic evaluation of staling in low-protein and gluten-free breads. Cereal Chemistry, 82, 328–335.

Biliaderis, C. G. (1992). Structures and phase transitions of starch in food systems. Food Technology, 6, 98–100.

Brennan, Ch. S. (2005). Dietary fibre, glycaemic response and diabetes. Molecular Nutrition & Food Research, 49, 560–570.

Christa, K., Soral-Śmietana, M., & Lewandowicz, G. (2009). Buckwheat starch: structure, functionality and enzyme in vitro susceptibility upon the roasting process. International Journal of Food Sciences and Nutrition, 60(S4), 140–154.

Dallmann, H. (1958). Porentabelle. Detmold: Moritz Schäfer.

Evans, I. D., & Haisman, D. R. (1982). The effect of solutes on the gelatinization temperature range of potato starch. Starch, 34, 224–231.

Fabjan, N., Rode, J., Koŝir, I. J., Zhang, Z., & Kreft, I. (2003). Tartary buckwheat (Fagopyrum tartaricum Gaertn.) as a source of dietary rutin and quercetin. Journal of Agricultural and Food Chemistry, 51, 6452–6455.

Fessas, D., Signorelli, M., Pagani, A., Mariotti, M., Iametti, S., & Schiraldi, A. (2008). Guidelines for buckwheat enriched bread. Thermal analysis approach. Journal of Thermal Analysis and Calorimetry, 91, 9–16.

Fujarczuk, M., & Żmijewski, M. (2009). Wheat bread quality depending on the addition of bran derived from various buckwheat varieties. Żywność Nauka Technologia Jakość, 6(67), 91–101.

Gallagher, E., Gormley, T. R., & Arendt, E. K. (2003). Crust and crumb characteristics of gluten-free bread. Journal of Food Engineering, 56, 153–161.

Gallagher, E., Gormley, T. R., & Arendt, E. K. (2004). Recent advances in the formulation of gluten-free cereal-based products. Trends in Food Science and Technology, 15, 143–152.

Giannou, V., & Tzia, G. (2007). Frozen dough bread: quality and textural behaviour during prolonged storage—prediction of final product characteristics. Journal of Food Engineering, 79, 929–934.

Gujral, H. S., Haros, M., & Rosell, C. M. (2003). Starch hydrolyzing enzymes for retarding the staling of rice bread. Cereal Chemistry, 80(6), 750–754.

Handoyo, T., Maeda, T., Urisu, A., Adachi, T., & Morita, M. (2006). Hypoallergenic buckwheat flour preparation by Rhizopus oligosporus and its application to soba noodle. Food Research International, 39, 598–605.

Kang, M. Y., Choi, Y. H., & Choi, H. C. (1997). Effects of gums, fats and gluten adding on processing and quality of milled rice bread. Korean Journal of Food Science and Technology, 29, 700–704.

Kato, N., Kayashita, J., & Tomotake, H. (2001). Nutritional and physiological functions of buckwheat protein. Recent Research in Developed Nutrition, 4, 113–119.

Kereliuk, G. R., & Sosulski, F. W. (1996). Comparison of starch from flint corn with that from dent corn and potato. Lebensmittel-Wissenschaft und Technologie, 29, 349–356.

Krupa, U., Rosell, C. M., Sadowska, J., & Soral-Śmietana, M. (2010). Bean starch as ingredient for gluten-free bread. Journal of Food Processing and Preservation, 34, 501–518.

Lazaridou, A., Duta, D., Papageorgiou, M., Belc, N., & Biliaderis, C. G. (2007). Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. Journal of Food Engineering, 79, 1033–1047.

León, A., Durán, E., & Benedito de Barber, C. (1997). A new approach to study starch changes occurring in the dough-baking process and during bread storage. Zeitschrift für Lebensmittel-Untersuchung und -Forschung, 204, 316–320.

Li, W., Lin, R., & Corke, H. (1997). Physicochemical properties of common and tartary buckwheat starch. Cereal Chemistry, 74, 79–82.

Lin, L.-Y., Liu, H.-M., Yu, Y.-W., Lin, S.-D., & Mau, J.-L. (2009). Quality and antioxidant property of buckwheat enhanced wheat bread. Food Chemistry, 112, 987–991.

Mohan Rao, V. N., & Skiner, G. E. (1986). Rheological properties of solid foods. In M. A. Rao & S. S. H. Rizvi (Eds.), Engineering properties of food. New York: Marcel Dekker Inc.

Oomah, B. D., & Mazza, G. (1996). Flavonoids and antioxidative activities in buckwheat. Journal of Agricultural and Food Chemistry, 44, 1746–1750.

Palou, E., López-Malo, A., Barbosa-Cánovas, G. V., Welti-Chanes, J., & Swanson, B. G. (1999). Polyphenoloxidase activity and color of blanched and high hydrostatic pressure treated banana puree. Journal of Food Science, 64, 42–45.

Relkin, P. (2005). Using thermal analysis and combined techniques for food characterization. Report on panel presentation. Journal of Thermal Analysis and Calorimetry, 80, 799–801.

Sabanis, D., Lebesi, D., & Tzia, C. (2009). Effect of dietary fibre enrichment on selected properties of gluten-free bread. LWT–Food Science and Technology, 42, 1380–1389.

Sanz-Penella, J. M., Tamayo-Ramos, J. A., Sanz, J., & Haros, M. (2009). Phytate reduction in bran-enriched bread by phytase-producing bifidobacteria. Journal of Agricultural and Food Chemistry, 57, 10239–10244.

Sanz-Penella, J. M., Wronkowska, M., Soral-Śmietana, M., Collar, C., & Haros, M. (2010). Impact of the addition resistant starch from modified pea starch on dough and bread performance. European Food Research and Technology, 231, 499–508.

Sikora, M., Kowalski, S., Krystyjan, M., Ziobro, R., Wrona, P., Curic, D., & LeBail, A. (2010). Starch gelatinization as measured by rheological properties of the dough. Journal of Food Engineering, 96, 505–509.

Singh, N., Singh, J., Kaur, L., Singh Sodhi, N., & Gill, S. (2003). Morphological, thermal and rheological properties of starches from different botanical sources. Food Chemistry, 81, 219–231.

Singh, N., Nakaura, Y., Inouchi, N., & Nishinari, K. (2007). Fine structure, thermal and viscoelastic properties of starches separated from Indica rice cultivars. Starch-Starke, 59, 10–20.

Spies, R. D., & Hoseney, R. C. (1982). Effect of sugar on starch gelatinization. Cereal Chemistry, 59, 128–131.

Steadman, K. J., Burgoon, M. S., Lewis, B. A., Edwardson, S. E., & Obendorf, R. L. (2001). Buckwheat seed miling fraction: description, macronutrient composition and dietary fibre. Journal Cereal Science, 33, 271–278.

Stibilj, V., Kreft, I., Smrkolj, P., & Osvald, J. (2004). Enhanced selenium content in buckwheat (Fagopyrum esculentum Moench) and pumpkin (Cucurbita pepo L.) seeds by foliar fertilisation. European Food Research and Technology, 219, 142–144.

Tang, Ch-H. (2007). Thermal properties of buckwheat proteins as related to their lipid contents. Food Research International, 40, 381–387.

Tomotake, H., Yamamoto, N., Yanaka, N., Ohinata, H., Yamazaki, R., Kayashita, J., & Kato, N. (2006). High protein buckwheat flour suppresses hypercholesterolemia in rats and gallstone formation in mice by hypercholesterolemic diet and body fat in rats because of its low protein digestibility. Nutrition, 22, 166–173.

Vader, L. W., Stepniak, D. T., Bunnik, E. M., Kooy, Y. M. C., De Haan, W., Drijfhout, J. W., Van Veelen, P. A., & Koning, F. (2003). Characterization of cereal toxicity for celiac disease patients based on protein homology in grains. Gastroenterology, 125, 1105–1113.

Wanatabe, M. (1998). Catechins as antioxidant from buckwheat (Fagopyrum esculentum Moench) groats. Journal of Agricultural and Food Chemistry, 46, 839–845.

Wei, Y., Hu, X., Zhang, G., & Ouyang, S. (2003). Studies on the amino acid and mineral content of buckwheat protein fractions. Nahrung/Food, 47, 114–116.

Wronkowska M., Soral-Śmietana M., Krupa U. (2008). Mieszanka bezglutenowa [Gluten-free formula]. Polish Pat. Spec. No P 386253 (in Polish).

Zhou, Y.-G., Wang, L.-J., Li, Y., Yang, B.-N., Bhandari, B., Chen, X. D., & Mao, Z.-H. (2009). Effect of water content on thermal behaviours of common buckwheat flour and starch. Journal of Engineering, 93, 242–248.

Acknowledgments

This work was financially supported by 2006PL0015 Project (PAS from Poland, CSIC from Spain) and Consolider Fun-C-Food CSD2007-00063 from the Ministry of Science and Innovation (MICINN-Spain). The authors thank Prof. Katarzyna Majewska for help in characterization of bread texture analysis.

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Wronkowska, M., Haros, M. & Soral-Śmietana, M. Effect of Starch Substitution by Buckwheat Flour on Gluten-Free Bread Quality. Food Bioprocess Technol 6, 1820–1827 (2013). https://doi.org/10.1007/s11947-012-0839-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-0839-0