Abstract

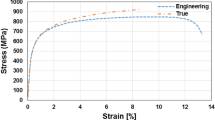

The nonlinear unloading behavior of three different commercial dual-phase steels (DP780 grade equivalent) was examined. These steels exhibited small variations in chemical composition (0.07 to 0.10 mass percent carbon) and martensite volume fraction (0.23 to 0.28), and they demonstrated similar hardening behavior. Uniaxial loading-unloading-loading tests were conducted at room temperature and quasi-static strain rates between engineering strains of 0.5 and 8%. Steel microstructures were examined using electron backscatter diffraction and nanoindentation techniques. The microplastic component of the unloading strain exhibited no dependence on the martensite volume fraction or the ferrite grain size within the small range encountered in this investigations. Instead, the magnitude of the microplastic component of the unloading strain increased as the strength ratio between the martensite and ferrite phases increased. Correspondingly, the apparent unloading modulus, or chord modulus, exhibited a greater reduction for equivalent increments of strain hardening as the strength ratio increased. These results suggest that springback can be reduced in structures containing two ductile phases if the strength ratio between the harder and softer phases is reduced.

Similar content being viewed by others

References

A. Col, Investigation on Press Forming Scatter Origin, Proceedings of the 6th International Conference on Material Forming, ESAFORM ‘03, 2003, p 183–186

K.S. Choi, W.N. Liu, X. Sun, M.A. Khaleel, and J.R. Fekete, Influence of Manufacturing Processes and Microstructures on the Performance and Manufacturability of Advanced High Strength Steels, J. Eng. Mater.-T. ASME, 2009, vol. 131, p 041205

R. Sohmshetty, R. Ramachandra, A. Bhimaraddi, and Z. Cedrix Xia, DP590 GI Mechanical Property Variability and Structural Response CAE Studies, SAE Technical Paper, 2009-01-0799

T. de Souza and B.F. Rolfe, Characterising Material and Process Variation Effects on Springback Robustness for Semi-cylindrical Sheet Metal Forming Processes, Int. J. Mech. Sci., 2010, 52, p 1756–1766

T. de Souza and B.F. Rolfe, Understanding Robustness of Springback in High Strength Steels, Int. J. Mech. Sci., 2013, 68, p 236–245

P. Chen and M. Koc, Simulation of springback variation in forming of advanced high strength steels, J. Mater. Process. Technol., 2007, 190, p 189–198

P. Chen, M. Koc, and M.L. Wenner, Experimental Investigation of Springback Variation in Forming of High Strength Steels, J. Manuf. Sci. Eng., 2008, 130, p 041006–041009

F. Morestin, M. Boivin, and C. Silva, Elasto Plastic Formulation Using a Kinematic Hardening Model for Springback Analysis in Sheet Metal Forming, J. Mater. Process. Technol., 1996, 56, p 619–630

F. Morestin and M. Boivin, On the Necessity of Taking into Account the Variation in the Young Modulus with Plastic Strain in Elastic-Plastic Software, Nucl. Eng. Des., 1996, 162, p 107–116

K. Yamaguchi, H. Adachi, and N. Takakura, Effects of Plastic Strain and Strain Path on Young’s Modulus of Sheet Metals, Met. Mater. Int., 1998, 4, p 420–445

F. Yoshida, T. Uemori, and K. Fujiwara, Elastic-Plastic Behavior of Steel Sheets Under In-plane Cyclic Tension-Compression at Large Strain, Int. J. Plast., 2002, 18, p 633–659

R.M. Cleveland and A.K. Ghosh, Inelastic Effects on Springback in Metals, Int. J. Plast, 2002, 18, p 769–785

L. Luo and A.K. Ghosh, Elastic and Inelastic Recovery after Plastic Deformation of DQSK Steel Sheet, J. Eng. Mater.-T ASME, 2003, 125, p 237–246

M. Yang, Y. Akiyama, and T. Sasaki, Evaluation of Change in Material Properties Due to Plastic Deformation, J. Mater. Process. Technol., 2004, 151, p 232–236

R. Pérez, J.A. Benito, and J.M. Prado, Study of the Inelastic Response of TRIP Steels After Plastic Deformation, ISIJ Int., 2005, 45, p 1925–1933

B.S. Levy, C.J. Van Tyne, Y.H. Moon, and C. Mikalsen, The Effective Unloading Modulus for Automotive Sheet Steels, SAE Technical Paper, 2006-01-0146

D. Fei and P. Hodgson, Experimental and Numerical Studies of Springback in Air V-bending Process for Cold Rolled TRIP Steels, Nucl. Eng. Des., 2006, 236, p 1847–1851

E.J. Pavlina, B.S. Levy, C.J. Van Tyne, S.O. Kwon, and Y.H. Moon, The Unloading Modulus of AKDQ Steel After Uniaxial and Near Plane-Strain Plastic Deformation, Int. J. Mod. Phys. B, 2008, 22, p 6070–6075

P.A. Eggertsen and K. Mattiasson, On the Modelling of the Bending-Unbending Behaviour for Accurate Springback Predictions, Int. J. Mech. Sci., 2009, 51, p 547–563

H.Y. Yu, Variation of Elastic Modulus During Plastic Deformation and Its Influence on Springback, Mater. Des., 2009, 30, p 846–850

P.A. Eggertsen and K. Mattiasson, On the Modeling of the Unloading Modulus for Metal Sheets, Int. J. Mater. Form., 2010, 3, p 127–130

L. Sun and R.H. Wagoner, Complex Unloading Behavior: Nature of the Deformation Its Consistent Constitutive Representation, Int. J. Plast., 2011, 27, p 1126–1144

H. Kim, C. Kim, F. Barlat, E. Pavlina, and M.-G. Lee, Nonlinear Elastic Behaviors of Low and High Strength Steels in Unloading and Reloading, Mater. Sci. Eng. A, 2013, 562, p 161–171

A. Govik, R. Rentmeester, and L. Nilsson, A Study of the Unloading Behaviour of Dual Phase Steel, Mater. Sci. Eng. A, 2014, 602, p 119–126

J. Mendiguren, J.J. Trujillo, F. Cortés, and L. Galdos, An Extended Elastic Law to Represent Non-linear Elastic Behaviour: Application in Computational Metal Forming, Int. J. Mech. Sci., 2013, 77, p 57–64

Y.P. Korkolis, N. Deng, and T. Kuwabara, Biaxial Unloading and Springback Behavior of Dual-Phase DP590 Steel Using Cruciform Specimens, Numisheet 2014, AIP Conf. Proc., 2013, 1567, p 700–704

E.J. Pavlina, M.-G. Lee, and F. Barlat, Observations on the Nonlinear Unloading Behavior of Advanced High Strength Steels, Metall. Mater. Trans. A, 2015, 46, p 18–22

J. Mendiguren, F. Cortés, X. Gómez, and L. Galdos, Elastic Behaviour Characterisation of TRIP 700 Steel by Means of Loading-Unloading Tests, Mater. Sci. Eng. A, 2015, 634, p 147–152

H. Mecking and U.F. Kocks, Kinetics of Flow and Strain-Hardening, Acta Metall., 1981, 29, p 1865–1875

G.E. Dieter, Mechanical Metallurgy, 3rd ed., McGraw-Hill, New York, 1986, p 140

L. Zhongua and G. Haicheng, Bauschinger Effect and Residual Phase Stresses in Two Ductile-Phase Steels: Part I. The Influence of Phase Stresses on the Bauschinger Effect, Metall. Trans. A, 1990, 21, p 717–724

L. Zhongua and G. Haicheng, Bauschinger Effect and Residual Phase Stresses in Two Ductile-Phase Steels: Part II. The Effect of Microstructure and Mechanical Properties of the Constituent Phases on Bauschinger Effect and Residual Phase Stresses, Metall. Trans. A, 1990, 21, p 725–732

S. Sriram, C. Wong, M. Huang, B. Yan, and D. Urban, Formability Characterization of a New Generation of High Strength Steels, Report No. 0012, American Iron and Steel Institute Technology Roadmap Program Office, Pittsburgh, PA, 2003

Q. Han, A. Asgari, P.D. Hodgson, and N. Stanford, Strain Partitioning in Dual Phase Steels Containing Tempered Martensite, Mater. Sci. Eng. A, 2014, 611, p 90–99

P.R. Rios, J.R.C. Guimarães, and K.K. Chawla, Modelling the Stress-Strain Curves of Dual-Phase Steels, Scr. Metall., 1981, 15, p 899–904

L. Duprez, B.C. DeCooman, and N. Akdut, High-Temperature Stress and Strain Partitioning in Duplex Stainless Steel, Z. Metallk., 2002, 93, p 236–243

B.M. Hance, Ph.D. Dissertation, University of Pittsburgh, 2005

M.F. Ashby, Deformation of Plastically Non-homogeneous Materials, Philos. Mag., 1970, 21, p 399–424

Standard Test Methods for Tension Testing of Metallic Materials, ASTM E8/8M-11, Annual Book of ASTM Standards, vol. 3.01, American Society for Testing and Materials, West Conshohocken, Pennsylvania

R.G. Davies, Edge Cracking in High Strength Steels, J. App. Metalworking, 1983, 2, p 293–299

P.M. Rice and R.E. Stoller, Correlation of Nanoindentation and Conventional Mechanical Property Measurements, Materials Research Society Symposium—Proceedings, 2001, vol. 649, p Q7.11.1–Q7.11.6

R.G. Davies, Influence of Martensite Composition and Content on the Properties of Dual Phase Steels, Metall. Trans. A, 1978, 9, p 671–679

P. Mencin, C.J. Van Tyne, and B.S. Levy, A Method for Measuring the Hardness of the Surface Layer on Hot Forging Dies Using a Nanoindenter, J. Mater. Eng. Perform., 2009, 18, p 1067–1072

G. Krauss, Martensitic Transformation, Structure and Properties in Hardenable Steels, Hardenability Concepts with Applications to Steel, D.V. Doane and J.S. Kirkaldy, Ed., AIME, 1978, p 229–248

E.J. Pavlina and C.J. Van Tyne, Correlation of Yield Strength and Tensile Strength with Hardness for Steels, J. Mater. Eng. Perform., 2008, 17, p 888–893

K. Hasegawa, K. Kawamura, T. Urabe, and Y. Hosoya, Effects of Microstructure on Stretch-Flange-Formability of 980 MPa Grade Cold-Rolled Ultra High Strength Steel Sheets, ISIJ Int., 2004, 44, p 603–609

Acknowledgments

The authors appreciate the financial support of the Australian Research Council (ARC Linkage Grant - LP120100111) and of Wuhan Iron and Steel Co. (WISCO).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pavlina, E.J., Lin, C., Mendiguren, J. et al. Effects of Microstructure on the Variation of the Unloading Behavior of DP780 Steels. J. of Materi Eng and Perform 24, 3737–3745 (2015). https://doi.org/10.1007/s11665-015-1671-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1671-2