Abstract

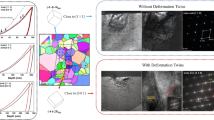

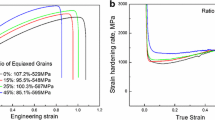

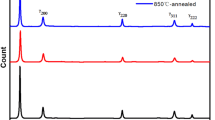

In the current study, the dependence of mechanical twinning on grain orientation and grain boundary characteristics was investigated using quasi in-situ tensile testing. The grains of three main orientations (i.e., 〈111〉, 〈110〉, and 〈100〉 parallel to the tensile axis (TA)) and certain characteristics of grain boundaries (i.e., the misorientation angle and the inclination angle between the grain boundary plane normal and the TA) were examined. Among the different orientations, 〈111〉 and 〈100〉 were the most and the least favored orientations for the formation of mechanical twins, respectively. The 〈110〉 orientation was intermediate for twinning. The annealing twin boundaries appeared to be the most favorable grain boundaries for the nucleation of mechanical twinning. No dependence was found for the inclination angle of annealing twin boundaries, but the orientation of grains on either side of the annealing twin boundary exhibited a pronounced effect on the propensity for mechanical twinning. Annealing twin boundaries adjacent to high Taylor factor grains exhibited a pronounced tendency for twinning regardless of their inclination angle. In general, grain orientation has a significant influence on twinning on a specific grain boundary.

Similar content being viewed by others

References

B.C. De Cooman, L. Chen, Han Soo Kim, Y. Estrin, S.K. Kim, and H. Voswinckel: in Microstructure and Texture in Steels, A Haldar, Suwas S, and Bhattacharjee D, eds., Springer, London, 2009, pp. 165–83.

B. De Cooman, K. Chin, and J. Kim: New Trends and Developments in Automotive Industry, Marcello Chiaberge, ed., InTech, 2011.

3. O. Bouaziz, S. Allain, C.P. Scott, P. Cugy, and D. Barbier: Curr. Opin. Solid State Mater. Sci., 2011, vol. 15, pp. 141–68.

4. O. Grässel, L. Krüger, G. Frommeyer, and L.W. Meyer: Int. J. Plast., 2000, vol. 16, pp. 1391–1409.

5. I. Karaman, H. Sehitoglu, K. Gall, Y.I. Chumlyakov, and H.J. Maier: Acta Mater., 2000, vol. 48, pp. 1345–59.

O. Bouaziz and N. Guelton: Mater. Sci. Eng. A, 2001, vols. 319–321, pp. 246–49.

S. Allain, J.P. Chateau, and O. Bouaziz: Mater. Sci. Eng. A, 2004, vols. 387–389, pp. 143–47.

S. Allain, J.P. Chateau, D. Dahmoun, and O. Bouaziz: Mater. Sci. Eng. A, 2004, vols. 387–389, pp. 272–76.

R.E. Reed-Hill: Phys. Metall. Princ., 1964.

F.D. Fischer, T. Schaden, F. Appel, and H. Clemens: Eur. J. Mech. A/Solids, 2003, vol. 22, pp. 709–26.

J.P. Hirth and J. Lothe: Theory of Dislocations, 1982.

12. J.A. Venables: Phil. Mag., 1961, vol. 6, pp. 379–96.

13. X.Z. Liao, Y.H. Zhao, S.G. Srinivasan, Y.T. Zhu, R.Z. Vallev, and D.V. Gunderov: Appl. Phys. Lett., 2004, vol. 84, pp. 592–94.

14. I. Gutierrez-Urrutia, S. Zaefferer, and D. Raabe: Mater. Sci. Eng. A, 2010, vol. 527, pp. 3552–60.

15. R. Ueji, N. Tsuchida, D. Terada, N. Tsuji, Y. Tanaka, A. Takemura, and K. Kunishige: Scripta Mater., 2008, vol. 59, pp. 963–66.

16. S. Mahajan and G.Y. Chin: Acta Metall., 1973, vol. 21, pp. 1353–63.

17. J.W. Christian and S. Mahajan: Progr. Mater. Sci., 1995, vol. 39, pp. 1–157.

18. D.Z. Li, Y.H. Wei, C.Y. Liu, L.F. Hou, D.F. Liu, and X.Z. Jin: J. Iron Steel Res. Int., 2010, vol. 17, pp. 67–73.

19. H. Beladi, P. Cizek, and P.D. Hodgson: Acta Mater., 2011, vol. 59, pp. 1482–92.

20. S. Sato, E.P. Kwon, M. Imafuku, K. Wagatsuma, and S. Suzuki: Mater. Charact., 2011, vol. 62, pp. 781–88.

A. Dumay, J.P. Chateau, S. Allain, S. Migot, and O. Bouaziz: Mater. Sci. Eng. A, 2008, vols. 483–484, pp. 184–87.

22. A. Saeed-Akbari, J. Imlau, U. Prahl, and W. Bleck: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 3076–90.

23. A. Soulami, K.S. Choi, Y.F. Shen, W.N. Liu, X. Sun, and M.A. Khaleel: Mater. Sci. Eng. A, 2011, vol. 528, pp. 1402–08.

S. Allain, J.P. Chateau, O. Bouaziz, S. Migot, and N. Guelton: Mater. Sci. Eng. A, 2004, vols. 387–389, pp. 158–62.

25. H. Beladi, N.T. Nuhfer, and G.S. Rohrer: Acta Mater., 2014, vol. 70, pp. 281–89.

26. H. Beladi and G.S. Rohrer: Acta Mater., 2013, vol. 61, pp. 1404–12.

27. G.S. Rohrer, D.M. Saylor, B. El Dasher, B.L. Adams, A.D. Rollett, and P. Wynblatt: Z. Metallkd., 2004, vol. 95, pp. 197–214.

28. I.J. Beyerlein, L. Capolungo, P.E. Marshall, R.J. McCabe, and C.N. Tomé: Phil. Mag., 2010, vol. 90, pp. 2161–90.

29. L. Capolungo, P.E. Marshall, R.J. McCabe, I.J. Beyerlein and C.N. Tomé: Acta Mater., 2009, vol. 57, pp. 6047–56.

T. Hildich, H. Beladi, P. Hodgson, and N. Stanford: Elsevier, Kidlington, ROYAUME-UNI, 2012.

V. Shterner: Ph.D. Thesis, Deakin University, Australia, 2015.

32. W.F. Hosford: The Mechanics of Crystals and Textured Polycrystals, Oxford Engineering Science Series 1993, Oxford University Press, New York, NY, 1993.

33. D.R. Steinmetz, T. Jäpel, B. Wietbrock, P. Eisenlohr, I. Gutierrez-Urrutia, A. Saeed–Akbari, T. Hickel, F. Roters, and D. Raabe: Acta Mater., 2013, vol. 61, pp. 494–510.

34. J.A. Venables: Phil. Mag., 1974, vol. 30, pp. 1165–69.

35. J.B. Cohen and J. Weertman: Acta Metall., 1963, vol. 11, pp. 996–98.

36. H. Fujita and T. Mori: Scripta Metall., 1975, vol. 9, pp. 631–36.

37. P. Yang, Q. Xie, L. Meng, H. Ding, and Z. Tang: Scripta Mater., 2006, vol. 55, pp. 629–31.

38. L. Meng, P. Yang, Q. Xie, H. Ding, and Z. Tang: Scripta Mater., 2007, vol. 56, pp. 931–34.

39. H. Beladi, I.B. Timokhina, Y. Estrin, J. Kim, B.C. De Cooman, and S.K. Kim: Acta Mater., 2011, vol. 59, pp. 7787–99.

S. Miura, J. Takamura, and N. Narita: Trans. JIM, 1968, vol. 9.

41. A.A. Saleh, A.A. Gazder, and E.V. Pereloma: Trans. Ind. Inst. Met., 2013, vol. 66, pp. 621–29.

42. A.A. Saleh, E.V. Pereloma, B. Clausen, D.W. Brown, C.N. Tomé, and A.A. Gazder: Mater. Sci. Eng. A, 2014, vol. 589, pp. 66–75.

S. Mahajan: in Encyclopedia of Materials: Science and Technology, K.H. Jürgen Buschow, R.W. Cahn, Merton C. Flemings, B. Ilschner, E.J. Kramer, S. Mahajan, and P. Veyssière, eds., Elsevier, Oxford, 2002, pp. 1–14.

44. M. Sachtleber, Z. Zhao, and D. Raabe: Mater. Sci. Eng. A, 2002, vol. 336, pp. 81–87.

Acknowledgments

Professor B.C. De Cooman is gratefully acknowledged for providing the TWIP steel used for this study. The authors also acknowledge the technical and scientific support of the Deakin Advanced Characterization Facility. This study was supported by an Australian Research Grant (Grant No. FL0992361). ADR acknowledges the support of the U.S. AFOSR under Grant No. FA9550-16-1-0105.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 15, 2017.

Rights and permissions

About this article

Cite this article

Shterner, V., Timokhina, I.B., Rollett, A.D. et al. The Role of Grain Orientation and Grain Boundary Characteristics in the Mechanical Twinning Formation in a High Manganese Twinning-Induced Plasticity Steel. Metall Mater Trans A 49, 2597–2611 (2018). https://doi.org/10.1007/s11661-018-4606-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4606-3