Abstract

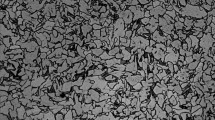

The phase transformation and precipitation in a high-strength low-alloy steel have been studied over a large range of cooling rates, and a continuous cooling transformation (CCT) diagram has been produced. These experiments are unique because the measurements were made from samples cooled directly from the melt, rather than in homogenized and re-heated billets. The purpose of this experimental design was to examine conditions pertinent to direct strip casting. At the highest cooling rates which simulate strip casting, the microstructure was fully bainitic with small regions of pearlite. At lower cooling rates, the fraction of polygonal ferrite increased and the pearlite regions became larger. The CCT diagram and the microstructural analysis showed that the precipitation of NbC is suppressed at high cooling rates, and is likely to be incomplete at intermediate cooling rates.

Similar content being viewed by others

References

Kopp, R. (1996). J. of Mat. Proc. Tech., 60, 1-9.

Zapuskalov, N. (2003). ISIJ International, 43, 1115-1127.

Strezov, L., Herbertson, J., & Belton, G. (2000). Metall. Mat. Trans. B, 31B, 1023-1030.

Ferry, M. (2006). Direct strip casting of metals and alloys. Woodhead, Cambridge.

Shiang, L., & Wray, P. (1989). Met. Trans. A, 20A, 1191-1198.

Malekjani, S., Timokhina, I., Wang, J., & Hodgson, P. (2013). Mat. Sci. & Eng. A, 581, 39-47.

Charleux, M., Poole, W., Militzer, M., & Deschamps, A. (2001). Met. and Mat. Trans. A, 32A, 1635-1647.

Zhang, Z., & Farrar, R. (1995). Atlas of continuous cooling transformation (CCT) diagrams applicable to low carbon low alloy weld metals. Woodhead, Cambridge.

Strezov, L., & Herbertson, J. (1998). ISIJ int., 38, 959-966.

Gault, B., Moody, M., Cairney, J., & Ringer, S. (2012). Atom Probe Microscopy. New York: Springer.

Miller, M., & Forbes, R. (2014). Atom-Probe Tomography: The Local Electrode Atom Probe. New York: Springer.

Avrami, M. (1939). The J. of Chem. Phys., 7 (12), 1103-1112.

Shrestha, S., Xie, K., Zhu, C., Ringer, S., Killmore, C., Carpenter, K., et al. (2013). Mat. Sci. & Eng. A, 568, 88-95.

Lee, Y. (2002). J. of Mat. Sci. Letters, 21, 1253-1255.

Andrews, K. (1965). J. Iron Steel Inst., 203, 721-727.

Dutta, B., & Sellars, C. (1987). Mat. Sci. and Tech., 3, 197-207.

Perrard, F., Deschamps, A., Bley, F., Donnadieu, P., & Maugis, P. (2006). J. of Applied Crystallo., 39, 473-482.

Evans, T., & Strezov, L. (2000). Metall. Mat. Trans. B, 31, 1081-1089.

Suehiro, M., Liu, Z., & Agren, J. (1996). Acta Mater., 44 (10), 4241-4251.

Challa, V., Zhou, W., Misra, R., O’Malley, R., & Janto, S. (2014). Mat. Sci & Eng. A, 595, 143-153.

P. Yan and H. Bhadeshia: Mater. Sci. Technol., 2014

Acknowledgments

The present work was carried out with the support of the Deakin Advanced Characterisation Facility, and was funded by the Australian Research Council’s Discovery Grant scheme (DP130101887). The authors would like to sincerely acknowledge David Gray who assisted in safely completing the steel melting and casting carried out in this project. We would also like to thank Dr. Ross Marceau whose comments on APT were not, in every instance, totally negative. Finally, the authors would like to thank the referee panel for providing useful comments which significantly improved the paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted on January 7, 2015.

Rights and permissions

About this article

Cite this article

Dorin, T., Stanford, N., Taylor, A. et al. Effect of Cooling Rate on Phase Transformations in a High-Strength Low-Alloy Steel Studied from the Liquid Phase. Metall Mater Trans A 46, 5561–5571 (2015). https://doi.org/10.1007/s11661-015-3173-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3173-0