Abstract

Background, aims and scope

The environmental aspects of companies and their products are becoming more significant in delivering competitive advantage. Formway Furniture, a designer and manufacturer of office furniture products, is a New Zealand-based company that is committed to sustainable development. It manufactures two models of the light, intuitive, flexible and environmental (LIFE) office chair: one with an aluminium base and one with a glass-filled nylon (GFN) base. It was decided to undertake a life cycle assessment (LCA) study of these two models in order to: (1) determine environmental hotspots in the life cycle of the two chairs (goal 1); (2) compare the life cycle impacts of the two chairs (goal 2); and (3) compare alternative potential waste-management scenarios (goal 3). The study also included sensitivity analysis with respect to recycled content of aluminium in the product.

Materials and methods

The LIFE chair models consist of a mix of metal and plastic components manufactured by selected Formway suppliers according to design criteria. Hence, the research methodology included determining the specific material composition of the two chair models and acquisition of manufacturing data from individual suppliers. These data were compiled and used in conjunction with pre-existing data, specifically from the ecoinvent database purchased in conjunction with the SimaPro7 LCA software, to develop the life cycle inventory of the two chair models. The life cycle stages included in the study extended from raw-material extraction through to waste management. Impact assessment was carried out using CML 2 baseline 2000, the methodology developed by Leiden University’s Institute for Environmental Sciences.

Results

This paper presents results for global warming potential (GWP100). The study showed a significant impact contribution from the raw-material extraction/refinement stage for both chair models; aluminium extraction and refining made the greatest contribution to GWP100. The comparison of the two LIFE chair models showed that the model with the aluminium base had a higher GWP100 impact than the model with the GFN base. The waste-management scenario compared the GWP100 result when (1) both chair models were sent to landfill and (2) steel and aluminium components were recycled with the remainder of the chair sent to landfill. The results showed that the recycling scenario contributed to a reduced GWP100 result. Since production and processing of aluminium was found to be significant, a sensitivity analysis was carried out to determine the impact of using aluminium with different recycled contents (0%, 34% and 100%) in both waste-management scenarios; this showed that increased use of recycled aluminium was beneficial. The recycling at end-of-life scenarios was modelled using two different end-of-life allocation approaches, i.e. consequential and attributional, in order to illustrate the variation in results caused by choice of allocation approach. The results using the consequential approach showed that recycling at end-of-life was beneficial, while use of the attributional method led to a similar GWP100 as that seen for the landfill scenario.

Discussion

The results show that the main hotspot in the life cycle is the raw-material extraction/refinement stage. This can be attributed to the extraction and processing of aluminium, a material that is energy intensive. The LIFE chair model with the aluminium base has a higher GWP100 as it contains more aluminium. Sensitivity analysis pertaining to the recycled content of aluminium showed that use of aluminium with high recycled content was beneficial; this is because production of recycled aluminium is less energy intensive than production of primary aluminium. The waste-management scenario showed that recycling at end-of-life resulted in a significantly lower GWP100 than landfilling at end-of-life. However, this result is dependent upon the modelling approach used for recycling.

Conclusions

With respect to goal 1, the study found that the raw-material extraction/refinement stage of the life cycle was a significant factor for both LIFE chair models. This was largely due to the use of aluminium in the product. For goal 2, it was found that the LIFE chair model with the aluminium base had a higher GWP100 than the GFN model, again due to the material content of the two models. Results for goal 3 illustrated that recycling at end-of-life is beneficial when using a system expansion (consequential) approach to model recycling; if an attributional ‘cut-off’ approach is used to model recycling at end-of-life, there is virtually no difference in the results between landfilling and recycling. Sensitivity analysis pertaining to the recycled content of aluminium showed that use of higher recycled contents leads to a lower GWP100 impact.

Recommendation and perspectives

Most of the GWP100 impact was contributed during the raw-material extraction/refinement stage of the life cycle; thus, the overall impact of both LIFE chair models may be reduced through engaging in material choice and supply chain environmental management with respect to environmental requirements. The study identified aluminium components as a major contributor to GWP100 for both LIFE chair models and also highlighted the sensitivity of the results to its recycled content. Thus, it is recommended that the use of aluminium in future product designs be limited unless it is possible to use aluminium with a high recycled content. With respect to waste management, it was found that a substantial reduction in the GWP100 impact would occur if the chairs are recycled rather than landfilled, assuming an expanding market for aluminium. Thus, recycling the two LIFE chair models at end-of-life is highly recommended.

Similar content being viewed by others

References

Babarenda Gamage G, Boyle C (2006) Developing the use of environmental impact assessment in commercial organisations: a case study of Formway furniture. Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, 31 May 31–2 June 2006, http://www.mech.kuleuven.be/lce2006/072.pdf

Baumann H, Tillman A (2004) The hitch hiker’s guide to LCA: an orientation in life cycle assessment methodology and application. Studentlitteratur, Lund, Switzerland

Bertram M (2006) The global and european dimension of aluminium recycling. International Aluminium Institute, European Aluminium Association and Organisation of European Aluminium Refiners and Remelters, http://www.aluminiumcentrum.nl/aluminiumcentrum.nl/files/Doc/Congres%202006/module%20a/2-Mrs._Marlen_Bertram.pdf

Ekvall T, Finnveden G (2000) The application of life cycle assessment to integrated solid waste management. Trans Instit Chem Eng, Part B 78:288–294

Ekvall T, Weidema BP (2004) System boundaries and input data in consequential life cycle inventory analysis. Int J LCA 9(3):161–171

EPD (2005) Product category rules (PCR) for preparing an environmental product declaration (EDP) for product group: Seating. Norwegian EPD Foundation, http://www.environdec.com/page.asp?id = 110&menu = 1,1,5&group = 36

Fet A, Skaar C (2006) Eco-labeling, product category rules and certification procedures based on ISO 14025 requirements. Int J LCA 11(1):49–54

Formway (2004) LIFE-You are liberated, Formway Furniture Ltd, http://www.formway.com/library/images/Life_Brochure_FW02_0704.pdf

Frischknecht R, Jungbluth N, Althaus H, Doka G, Dones R, Heck T, Hellweg S, Hischier R, Nemecek T, Rebitzer G, Spielmann M (2005) The ecoinvent database: overview and methodological framework. Int J LCA 10(1):3–9

Guinée JB, Gorree R, Heijungs G, Huppes R, Kleijn R, Udo de Haes HA (2000) Environmental life cycle assessment: backgrounds. Centre of Environmental Science (CML). Leiden University, The Netherlands

Guinée J, Gorree M, Heijungs R, Huppes G, Kleijn R, Udo de Haes HA, Van der Voet E, Wrisberg M (2002) Life cycle assessment. An operational guide to ISO standards, vols 1, 2, 3. Centre of Environmental Science (CML). Leiden University, The Netherlands

Heijungs R, Guinée JB (2007) Allocation and ‘what-if’ scenarios in life cycle assessment of waste management systems. Waste Manag 27(8):997–1005

ISO (1997) ISO 14040 Environmental management, life cycle assessment, principles and framework. International Standards Organization, Geneva, Switzerland

ISO (1999) ISO 14041: Environmental management—life cycle assessment—goal and scope definition and inventory analysis. International Standards Organization, Geneva, Switzerland

ISO (2004) ISO 14001 Environmental management systems—specifications with guidance for use. International Standards Organization, Geneva, Switzerland

ISO (2006) ISO 14044: Environmental management—life cycle assessment—requirements and guidelines. International Standards Organization, Geneva, Switzerland

Klöpffer W (1996) Allocation rules for open-loop recycling in life cycle assessment—a review. Int J LCA 1(1):27–31

Lewis L, Gertsakis J, Grant T, Morelli N, Sweatman A (2001) Design + environment: A global guide to designing greener goods. Greenleaf Publishing, Sheffield, UK

NHO (2006) Norwegian environmental declarations (EPD) and product category rules (PCR), http://www.nho.no/article.php?articleID = 15516&categoryID = 90

PRé Consultants (2006) SimaPro v. 7.0. Amersfoort, The Netherlands

Rossi M, Charon S, Wing G, Ewell J (2006) Design for the next generation: incorporating cradle-to-cradle design into Herman Miller Products. J Indust Ecol 10(4):193–210

SETAC (1993) Guidelines for life-cycle assessment: A ‘Code of Practice’. From the SETAC workshop held at Sesimbra, Portugal, 30 March–April 1993, Society of Environmental Toxicology and Chemistry, USA

Soanes C, Stevenson A (eds) (2005) The Oxford Dictionary of English (rev ed). Oxford University Press, Oxford Reference Online, http://www.oxfordreference.com.ezproxy.auckland.ac.nz/views/GLOBAL.html

Steelcase (2004) Think: environmental product declaration: a presentation of quantified environmental life cycle product information for the Think work chair in North America, Steelcase Inc

Todd J, Curran M (1999) Streamlined life-cycle assessment: a final report from the SETAC North America Streamlined LCA Workgroup. Society of Environmental Toxicology and Chemistry and SETAC Foundation for Environmental Education

Udo de Haes HA, Jolliet O, Finnveden G, Hauschild M, Krewitt W, Müller-Wenk R (1999a) Best available practice regarding impact categories and category indicators in life cycle impact assessment, Part 1. Int J LCA 4(2):66–74

Udo de Haes HA, Jolliet O, Finnveden G, Hauschild M, Krewitt W, Müller-Wenk R (1999b) Best available practice regarding impact categories and category indicators in life cycle impact assessment, Part 2. Int J LCA 4(3):167–174

Weidema B (2001) Avoiding co-product allocation in life-cycle assessment. J Indust Ecol 4(3):11–33

Acknowledgements

This research was financially supported by the New Zealand Foundation for Research, Science and Technology (Technology Industry Fellowship grants no. FMYX0506 and FMYX0502). Dr Sarah McLaren’s involvement was funded through the New Zealand Foundation for Research, Science and Technology programme ‘Building Capacity for Sustainable Development: the Enabling Research’ (C09X0310). Additionally, we extend our sincere thanks to Formway Furniture Ltd. for its support and participation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Barbara Nebel

Appendices

Appendix 1

-

(1)

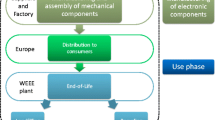

Raw-material extraction and refinement. The materials required for manufacturing the LIFE chair are given in Fig. 1. The data used for raw-material extraction and refinement were taken from the ecoinvent database. The electrical energy models were modified to reflect the respective locations as shown in Table 2. Note that transport of materials from raw-material extraction and refinement to component manufacture was not considered due to insufficient data. This is because suppliers have numerous and variable sources of material supply according to market criteria such as material availability and price.

-

(2)

Manufacture of LIFE components. At the component manufacture stage, suppliers use extracted and refined materials to manufacture components according to design criteria. The main processes used by Formway’s suppliers are listed in Table 3. Data from suppliers were used to modify existing records in the ecoinvent database so as to determine a Formway-specific case.

-

(1)

Transport of components to Formway. The transport scenario considers transportation of components from suppliers to final assembly at Formway via road and sea as given in Table 4. Where distances of less than 100 km are considered, small trucks (16 tonnes) are used for transport. For distances greater than 100 km, large trucks (32 tonnes) are used. Commercial freighters are used for all sea transport.

-

(2)

Assembly and packaging of LIFE. The components are assembled using hand and power tools at Formway’s Wellington plant in New Zealand. Assembling only requires electrical energy and manpower.

-

(3)

Transport of product to customer and to waste management. This study considers the transport scenario where the assembled and packaged LIFE chairs are transported to a customer in Sydney, Australia. The respective transport modes and distances are given in Table 5. Where distances of less than 100 km are considered, small trucks (16 tonnes) are used for transport. For distances greater than 100 km, large trucks (32 tonnes) are used, and freighters are used for sea transport.

-

(4)

Use phase and waste management. No environmental exchange takes place during use of the chairs since the product does not require energy or water to function, and it was assumed that no significant repairs are made during its life. The only foreseeable need was cleaning, which includes wiping the surface to clear dust or any marks, and is expected to have negligible environmental consequences.

Appendix 2

Figure 9

Rights and permissions

About this article

Cite this article

Babarenda Gamage, G., Boyle, C., McLaren, S.J. et al. Life cycle assessment of commercial furniture: a case study of Formway LIFE chair. Int J Life Cycle Assess 13, 401–411 (2008). https://doi.org/10.1007/s11367-008-0002-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-008-0002-3