Abstract

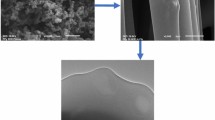

We report an electrospun & thermally stable micro-fibers of poly(1,6-heptadiyne) (PHD), modified with ABS. Developed micro-fibers demonstrated hydrophobicity (WCA~145o ± 2o), and exhibited hierarchical surface morphology (confirmed by FESEM analysis). Simulation study showed Chi parameter i.e. χc = 7.88, & free energy of mixing i.e. 4.67 kcal/mol, thereby demonstrating its feasibility for electrospinning. PHD/ABS microfibers demonstrated low ice-adhesion ability, where, it effectively removed frozen water droplets in 8 s from hydrophobic surface, under an air-stream rate of 78 kPa/s. High thermal stability (200 °C), hydrophobicity and low ice-adhesion ability, demonstrate that PHD/ABS microfibers can be effectively used for multifunctional engineering/industrial applications.

Fabrication of poly (1,6-heptadiyne)/ABS microfibers via electrospinning.

Similar content being viewed by others

References

Schlaich C, Wei Q, Haag R (2017) Mussel-inspired Polyglycerol coatings with controlled wettability: from Superhydrophilic to Superhydrophobic surface coatings. Langmuir 33:9508–9520. https://doi.org/10.1021/acs.langmuir.7b01291

Almohammadi H, Amirfazli A (2017) Understanding the drop impact on moving hydrophilic and hydrophobic surfaces. Soft Matter 13:2040–2053. https://doi.org/10.1039/C6SM02514E

Al-Azawi A, Latikka M, Jokinen V et al (2017) Friction and wetting transitions of magnetic droplets on micropillared Superhydrophobic surfaces. Small 13:1700860. https://doi.org/10.1002/smll.201700860

Gore PM, Balakrishnan S, Kandasubramanian B (2019) Superhydrophobic corrosion inhibtion polymer coatings. Superhydrophobic polymer coatings: fundamentals, design, fabrication, and applications1st edn. Elsevier, Amsterdam, pp 1–22

Xue C-H, Li Y-R, Zhang P, Ma JZ, Jia ST (2014) Washable and Wear-resistant Superhydrophobic surfaces with self-cleaning property by chemical etching of fibers and Hydrophobization. ACS Appl Mater Interfaces 6:10153–10161. https://doi.org/10.1021/am501371b

Liu D, Wang Q, Shen W, Wang D (2017) Self-cleaning antireflective coating with a hierarchical texture for light trapping in micromorph solar cells. J Mater Chem C 5:103–109. https://doi.org/10.1039/C6TC03152H

Gupta P, Kandasubramanian B (2017) Directional fluid gating by Janus membranes with heterogeneous wetting properties for selective oil–water separation. ACS Appl Mater Interfaces 9:19102–19113. https://doi.org/10.1021/acsami.7b03313

Sahoo BN, Balasubramanian K, Sucheendran M (2015) Thermally triggered transition of superhydrophobic characteristics of micro- and nanotextured multiscale rough surfaces. J Phys Chem C:150610094322003. https://doi.org/10.1021/acs.jpcc.5b02917

Zhang P, Lin L, Zang D et al (2017) Designing bioinspired anti-biofouling surfaces based on a Superwettability strategy. Small 13:1503334. https://doi.org/10.1002/smll.201503334

Gore PM, Naebe M, Wang X, Kandasubramanian B (2019) Progress in silk materials for integrated water treatments: fabrication, modification and applications. Chem Eng J 374:437–470. https://doi.org/10.1016/j.cej.2019.05.163

Gore PM, Khurana L, Siddique S, Panicker A, Kandasubramanian B (2018) Ion-imprinted electrospun nanofibers of chitosan/1-butyl-3-methylimidazolium tetrafluoroborate for the dynamic expulsion of thorium (IV) ions from mimicked effluents. Environ Sci Pollut Res 25:3320–3334. https://doi.org/10.1007/s11356-017-0618-6

Gore P, Khraisheh M, Kandasubramanian B (2018) Nanofibers of resorcinol–formaldehyde for effective adsorption of As (III) ions from mimicked effluents. Environ Sci Pollut Res 25:11729–11745. https://doi.org/10.1007/s11356-018-1304-z

Rajhans A, Gore PM, Siddique SK, Kandasubramanian B (2019) Ion-imprinted nanofibers of PVDF/1-butyl-3-methylimidazolium tetrafluoroborate for dynamic recovery of europium (III) ions from mimicked effluent. J Environ Cheml Eng 7:103068. https://doi.org/10.1016/j.jece.2019.103068

Gore PM, Kandasubramanian B (2018) Heterogeneous wettable cotton based superhydrophobic Janus biofabric engineered with PLA/functionalized-organoclay microfibers for efficient oil–water separation. J Mater Chem A 6:7457–7479. https://doi.org/10.1039/C7TA11260B

Gore PM, Dhanshetty M, Kandasubramanian B (2016) Bionic creation of Nano-engineered Janus fabric for selective oil/organic solvent absorption. RSC Adv. https://doi.org/10.1039/C6RA24106A

Mishra P, Balasubramanian K (2014) Nanostructured microporous polymer composite imprinted with superhydrophobic camphor soot, for emphatic oil–water separation. RSC Adv 4:53291–53296. https://doi.org/10.1039/C4RA07410F

Arora R, Balasubramanian K (2014) Hierarchically porous PVDF/nano-SiC foam for distant oil-spill cleanups. RSC Adv 4:53761–53767. https://doi.org/10.1039/C4RA09245G

Onda T, Shibuichi S, Satoh N, Tsujii K (1996) Super-water-repellent fractal surfaces. Langmuir 12:2125–2127. https://doi.org/10.1021/la950418o

Bazin D, Faure C (2017) Superhydrophobic, highly adhesive arrays of copper hollow spheres produced by electro-colloidal lithography. Soft Matter 13:5500–5505. https://doi.org/10.1039/C7SM01256J

Zhuang A, Liao R, Dixon SC et al (2017) Transparent superhydrophobic PTFE films via one-step aerosol assisted chemical vapor deposition. RSC Adv 7:29275–29283. https://doi.org/10.1039/C7RA04116K

Yuan Z, Chen H, Tang J et al (2007) A novel preparation of polystyrene film with a superhydrophobic surface using a template method. J Phys D Appl Phys 40:3485–3489. https://doi.org/10.1088/0022-3727/40/11/033

Su X, Li H, Lai X, Zhang L, Wang J, Liao X, Zeng X (2017) Vapor–liquid sol–gel approach to fabricating highly durable and robust Superhydrophobic Polydimethylsiloxane@silica surface on polyester textile for oil–water separation. ACS Appl Mater Interfaces 9:28089–28099. https://doi.org/10.1021/acsami.7b08920

Qing Y, Hu C, Yang C, An K, Tang F, Tan J, Liu C (2017) Rough structure of Electrodeposition as a template for an Ultrarobust self-cleaning surface. ACS Appl Mater Interfaces 9:16571–16580. https://doi.org/10.1021/acsami.6b15745

Wu M, An N, Li Y, Sun J (2016) Layer-by-layer assembly of fluorine-free polyelectrolyte–surfactant complexes for the fabrication of self-healing Superhydrophobic films. Langmuir 32:12361–12369. https://doi.org/10.1021/acs.langmuir.6b02607

Hu Z, Berry RM, Pelton R, Cranston ED (2017) One-pot water-based hydrophobic surface modification of cellulose Nanocrystals using plant polyphenols. ACS Sustain Chem Eng 5:5018–5026. https://doi.org/10.1021/acssuschemeng.7b00415

Sahoo BN, Kandasubramanian B (2014) Photoluminescent carbon soot particles derived from controlled combustion of camphor for superhydrophobic applications. RSC Adv 4:11331. https://doi.org/10.1039/c3ra46193a

Tian X, Shaw S, Lind KR, Cademartiri L (2016) Thermal processing of silicones for Green, scalable, and healable Superhydrophobic coatings. Adv Mater 28:3677–3682. https://doi.org/10.1002/adma.201506446

Murdoch TJ, Willott JD, de Vos WM et al (2016) Influence of anion Hydrophilicity on the conformation of a hydrophobic weak polyelectrolyte brush. Macromolecules 49:9605–9617. https://doi.org/10.1021/acs.macromol.6b01897

Harvey BG, Guenthner AJ, Koontz TA et al (2016) Sustainable hydrophobic thermosetting resins and polycarbonates from turpentine. Green Chem 18:2416–2423. https://doi.org/10.1039/C5GC02893K

Chung C-Y, Warkiani ME, Mesgari S et al (2015) Thermoset polyester-based superhydrophobic microchannels for nanofluid heat transfer applications. In: Eggleton BJ, Palomba S (eds) Sydney. New South Wales, Australia, p 96680D

Cao W-T, Liu Y-J, Ma M-G, Zhu J-F (2017) Facile preparation of robust and superhydrophobic materials for self-cleaning and oil/water separation. Colloids Surf A Physicochem Eng Asp 529:18–25. https://doi.org/10.1016/j.colsurfa.2017.05.064

Söz CK, Yilgör E, Yilgör I (2016) Simple processes for the preparation of superhydrophobic polymer surfaces. Polymer 99:580–593. https://doi.org/10.1016/j.polymer.2016.07.051

Haselwander TFA, Heitz W, Krügel SA, Wendorff JH (1996) Polynorbornene: synthesis, properties and simulations. Macromol Chem Phys 197:3435–3453. https://doi.org/10.1002/macp.1996.021971029

Shang Y, Si Y, Raza A et al (2012) An in situ polymerization approach for the synthesis of superhydrophobic and superoleophilic nanofibrous membranes for oil–water separation. Nanoscale 4:7847. https://doi.org/10.1039/c2nr33063f

Sung G, Choi M-C, Nagappan S, Lee WK, Han M, Ha CS (2013) Polynorbornene/fluorosilica hybrids for hydrophobic and oleophobic coatings. Polym Bull 70:619–630. https://doi.org/10.1007/s00289-012-0882-z

Ruffoni A, Cavanna MV, Argentiere S et al (2016) Aqueous self-assembly of short hydrophobic peptides containing norbornene amino acid into supramolecular structures with spherical shape. RSC Adv 6:90754–90759. https://doi.org/10.1039/C6RA17116H

Grove NR, Kohl PA, Bidstrup Allen SA et al (1999) Functionalized polynorbornene dielectric polymers: adhesion and mechanical properties. J Polym Sci B Polym Phys 37:3003–3010. https://doi.org/10.1002/(SICI)1099-0488(19991101)37:21<3003::AID-POLB10>3.0.CO;2-T

Janiak C, Lassahn PG (2001) The vinyl Homopolymerization of Norbornene. Macromol Rapid Commun 22:479–493. https://doi.org/10.1002/1521-3927(20010401)22:7<479::AID-MARC479>3.0.CO;2-C

Maier G (2001) Low dielectric constant polymers for microelectronics. Prog Polym Sci 26:3–65. https://doi.org/10.1016/S0079-6700(00)00043-5

Rao NV, Mane SR, Kishore A, Das Sarma J, Shunmugam R (2012) Norbornene derived doxorubicin copolymers as drug carriers with pH responsive Hydrazone linker. Biomacromolecules 13:221–230. https://doi.org/10.1021/bm201478k

Bhattacharya S, Sarkar S, Shunmugam R (2013) Unique norbornene polymer based “in-field” sensor for As(iii). J Mater Chem A 1:8398. https://doi.org/10.1039/c3ta11587a

Sarkar S, Shunmugam R (2014) Polynorbornene derived 8-hydroxyquinoline paper strips for ultrasensitive chemical nerve agent surrogate sensing. Chem Commun 50:8511–8513. https://doi.org/10.1039/C4CC03361B

Mukherjee M, Ganivada MN, Venu P et al (2016) Unique nanotubes from polynorbornene derived graphene sheets. RSC Adv 6:40691–40697. https://doi.org/10.1039/C6RA05840J

Mane SR, Sarkar SNVR et al (2015) An efficient method to prepare a new class of regioregular graft copolymer via a click chemistry approach. RSC Adv 5:74159–74161. https://doi.org/10.1039/C5RA12510C

Fujiwara M, Shirato Y, Owari H et al (2007) Novel optical/electrical printed circuit board with Polynorbornene optical waveguide. Jpn J Appl Phys 46:2395–2400. https://doi.org/10.1143/JJAP.46.2395

Cao K, Siepermann CP, Yang M et al (2013) Reactive aramid nanostructures as high-performance polymeric building blocks for advanced composites. Adv Funct Mater 23:2072–2080. https://doi.org/10.1002/adfm.201202466

Joseph PJ, Kelleher HA, Allen SAB, Kohl PA (2005) Improved fabrication of micro air-channels by incorporation of a structural barrier. J Micromech Microeng 15:35–42. https://doi.org/10.1088/0960-1317/15/1/006

Hess-Dunning AE, Smith RL, Zorman CA (2014) Development of polynorbornene as a structural material for microfluidics and flexible BioMEMS. J Appl Polym Sci 131. https://doi.org/10.1002/app.40969

Magisetty R, Kumar P, Gore PM et al (2019) Electronic properties of poly(1,6-heptadiynes) electrospun fibrous non-woven mat. Mater Chem Phys 223:343–352. https://doi.org/10.1016/j.matchemphys.2018.11.020

Magisetty R, Kumar P, Kumar V, Shukla A, Kandasubramanian B, Shunmugam R (2018) NiFe2O4/poly(1,6-heptadiyne) Nanocomposite energy-storage device for electrical and electronic applications. ACS Omega 3:15256–15266. https://doi.org/10.1021/acsomega.8b02306

Huang Z-M, Zhang Y-Z, Kotaki M, Ramakrishna S (2003) A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol 63:2223–2253. https://doi.org/10.1016/S0266-3538(03)00178-7

Gore PM, Zachariah S, Gupta P, K. B (2016) Multifunctional nano-engineered and bio-mimicking smart superhydrophobic reticulated ABS/fumed silica composite thin films with heat-sinking applications. RSC Adv 6:105180–105191. https://doi.org/10.1039/C6RA16781K

Khurana L, Balasubramanian K (2016) Adsorption potency of imprinted starch/PVA polymers confined ionic liquid with molecular simulation framework. J Environ Cheml Eng 4:2147–2154. https://doi.org/10.1016/j.jece.2016.03.032

Yadav R, Naebe M, Wang X, Kandasubramanian B (2016) Temperature assisted in-situ small angle X-ray scattering analysis of Ph-POSS/PC polymer nanocomposite. Sci Rep 6:6–9. https://doi.org/10.1038/srep29917

Wenzel RN (1936) Resistance of solid surfaces to wetting by water. Ind Eng Chem 28:988–994. https://doi.org/10.1021/ie50320a024

Cassie ABD, Baxter S (1944) Wettability of porous surfaces. Trans Faraday Soc 40:546. https://doi.org/10.1039/tf9444000546

Packham DE (1996) Work of adhesion: contact angles and contact mechanics. Int J Adhes Adhes 16:121–128. https://doi.org/10.1016/0143-7496(95)00034-8

Simon SM, Chandran A, George G, Sajna MS, Valparambil P, Kumi-Barmiah E, Jose G, Biju PR, Joseph C, Unnikrishnan NV (2018) Development of thick Superhydrophilic TiO2–ZrO2 transparent coatings realized through the inclusion of poly(methyl methacrylate) and Pluronic-F127. ACS Omega 3:14924–14932. https://doi.org/10.1021/acsomega.8b01940

Jose JP, Abraham J, Maria HJ et al (2016) Contact angle studies in XLPE hybrid Nanocomposites with inorganic Nanofillers. Macromol Symp 366:66–78. https://doi.org/10.1002/masy.201650048

Gore PM, Purushothaman A, Naebe M et al (2019) Nanotechnology for oil-water separation. In: advanced research in Nanosciences for water technology1st edn. Springer Science+Business Media, New York

Perry RH, Green DW, Maloney JO (1984) Perry’s chemical engineers’ handbook6th edn. McGraw-Hill, New York

Roy BN (2002) Fundamentals of classical and statistical thermodynamics. Wiley, West Sussex

Edmister WC, Lee BI (1984) Applied hydrocarbon thermodynamics2nd edn. Gulf Pub. Co, Houston

Wei C, Jin B, Zhang Q et al (2018) Anti-icing performance of super-wetting surfaces from icing-resistance to ice-phobic aspects: robust hydrophobic or slippery surfaces. J Alloys Compd 765:721–730. https://doi.org/10.1016/j.jallcom.2018.06.041

Elsharkawy M, Tortorella D, Kapatral S, Megaridis CM (2016) Combating frosting with joule-heated liquid-infused Superhydrophobic coatings. Langmuir 32:4278–4288. https://doi.org/10.1021/acs.langmuir.6b00064

Kuptsov AH, Zhizhin GN (1998) Handbook of fourier transform Raman and infrared spectra of polymers. Elsevier, Amsterdam, New York

Jeon S, Shim C, Cho CS et al (2000) Catalytic cyclopolymerization and copolymerization of 1,6-heptadiynes by Mo(CO)6. J Polym Sci A Polym Chem 38:2663–2670. https://doi.org/10.1002/1099-0518(20000801)38:15<2663::AID-POLA50>3.0.CO;2-6

Song W, Han H, Liao X et al (2014) Metathesis Cyclopolymerization of Imidazolium-functionalized 1,6-Heptadiyne toward Polyacetylene Ionomer. Macromolecules 47:6181–6188. https://doi.org/10.1021/ma501217b

Ganivada MN, Kumar P, Shunmugam R (2015) A unique polymeric gel by thiol–alkyne click chemistry. RSC Adv 5:50001–50004. https://doi.org/10.1039/C5RA06339F

Mahalingam S, Homer-Vanniasinkam S, Edirisinghe M (2019) Novel pressurised gyration device for making core-sheath polymer fibres. Mater Des 178:107846. https://doi.org/10.1016/j.matdes.2019.107846

Heseltine PL, Ahmed J, Edirisinghe M (2018) Developments in pressurized gyration for the mass production of polymeric fibers. Macromol Mater Eng 303:1800218. https://doi.org/10.1002/mame.201800218

Hong X, Mahalingam S, Edirisinghe M (2017) Simultaneous application of pressure-infusion-gyration to generate polymeric Nanofibers. Macromol Mater Eng 302:1600564. https://doi.org/10.1002/mame.201600564

Acknowledgements

The authors are thankful to Dr. C. P. Ramanarayanan, Vice-Chancellor of DIAT (DU), Pune for motivation and support. The authors are also thankful to anonymous reviewers for their valuable suggestions, and comments, which helped in improving the quality of the manuscript.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, P., Gore, P.M., Magisetty, R. et al. Poly(1,6-heptadiyne)/ABS functionalized microfibers for hydrophobic applications. J Polym Res 27, 14 (2020). https://doi.org/10.1007/s10965-019-1981-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1981-4