Abstract

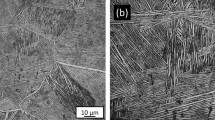

A Ti–6Al–4V alloy was heat-treated to give two types of microstructures with different volume fraction of equiaxed α phase and lamellar (α + β) microstructure. Disks were cut from the heat-treated rods and processed by quasi-constrained high-pressure torsion (HPT) at room temperature with an applied pressure of 6.0 GPa and torsional straining from 1/4 to 20 turns. The results show that there is a gradual evolution of homogeneity in microhardness and grain size with increasing numbers of revolutions in HPT such that the microhardness values attain a maximum constant value across the disk after processing by HPT for 10 turns and the measured equilibrium grain sizes after 20 turns are ~130 nm in Ti64-1 and ~70 in Ti64-2. The results show also that a larger fraction of lamellar (α + β) in the microstructure of Ti–6Al–4V leads to a higher hardenability after processing by HPT.

Similar content being viewed by others

References

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:104

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT (2006) JOM 58(4):33

Zhilyaev AP, Langdon TG (2008) Prog Mater Sci 53:893

Zhilyaev AP, Kim BK, Nurislamova GV, Baró MD, Szpunar JA, Langdon TG (2002) Scripta Mater 46:575

Zhilyaev AP, Nurislamova GV, Kim BK, Baró MD, Szpunar JA, Langdon TG (2003) Acta Mater 51:753

Zhilyaev AP, Kim BK, Szpunar JA, Baró MD, Langdon TG (2005) Mater Sci Eng A381:377

Zhu YT, Lowe TC, Langdon TG (2004) Scripta Mater 51:825

Yapici GG, Karaman I, Luo ZP (2006) Acta Mater 54:3755

Tabachnikova ED, Podolskiy AV, Bengus VZ, Smirnov SN, Bidylo MI, Csach K, Miskuf J, Saitova LR, Semenova IP, Valiev RZ (2009) Mater Sci Eng A503:106

Saitova LR, Höppel HW, Göken M, Semenova IP, Raab GI, Valiev RZ (2009) Mater Sci Eng A503:145

Semenova IP, Yakushina EB, Nurgaleeva VV, Valiev RZ (2009) Int J Mater Res 100:1691

Stolyarov VV, Shestakova LO, Zhu YT, Valiev RZ (1999) Nanostruct Mater 12:923

Sergueeva AV, Stolyarov VV, Valiev RZ, Mukherjee AK (2000) Scripta Mater 43:819

Mishra RS, Stolyarov VV, Echer C, Valiev RZ, Mukherjee AK (2001) Mater Sci Eng A298:44

Sergueeva AV, Stolyarov VV, Valiev RZ, Mukherjee AK (2002) Mater Sci Eng A323:318

Wang YC, Langdon TG (2013) Mater Sci Eng A559:861

Xu C, Horita Z, Langdon TG (2008) Acta Mater 56:5168

Figueiredo RB, Cetlin PR, Langdon TG (2011) Mater Sci Eng A528:8198

Figueiredo RB, Pereira PHR, Aguilar MTP, Cetlin PR, Langdon TG (2012) Acta Mater 60:3190

Serre P, Figueiredo RB, Gao N, Langdon TG (2011) Mater Sci Eng A528:3601

Kawasaki M, Langdon TG (2008) Mater Sci Eng A498:341

Vorhauer A, Pippan R (2004) Scripta Mater 51:921

Zhilyaev AP, McNelley TR, Langdon TG (2007) J Mater Sci 42:1517. doi:10.1007/s10853-006-0628-0

Kawasaki M, Ahn B, Langdon TG (2010) Acta Mater 58:919

Sabbaghianrad S, Kawasaki M, Langdon TG (2012) J Mater Sci 47:7789. doi:10.1007/s10853-012-6524-x

Wongsa-Ngam J, Kawasaki M, Langdon TG (2012) J Mater Sci 47:7782. doi:10.1007/s10853-012-6587-8

Langdon TG (2007) Mater Sci Eng A462:3

Zhilyaev AP, Oh-ishi K, Langdon TG, McNelley TR (2005) Mater Sci Eng A410–411:277

An XH, Wu SD, Zhang ZF, Figueiredo RB, Gao N, Langdon TG (2010) Scripta Mater 63:560

Valiev RZ, Ivanisenko YuV, Rauch EF, Baudelet B (1996) Acta Mater 44:4705

Wetscher F, Vorhauer A, Stock R, Pippan R (2004) Mater Sci Eng A387–389:809

Acknowledgements

This study was supported in part by the National Key Laboratory of Science and Technology on Materials under Shock and Impact under funding No. 9140A12060110BQ01, in part by the National Science Foundation of the United States under Grant No. DMR-1160966 and in part by the European Research Council under ERC Grant Agreement No. 267464-SPDMETALS.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y.C., Langdon, T.G. Effect of heat treatment on microstructure and microhardness evolution in a Ti–6Al–4V alloy processed by high-pressure torsion. J Mater Sci 48, 4646–4652 (2013). https://doi.org/10.1007/s10853-012-7071-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-7071-1