Abstract

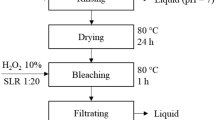

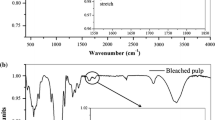

This paper reports the possibility of producing cellulose nanofiber from softwood pulp using a simple ball milling technique under ambient pressure and at room temperature. The effects of milling conditions including the ball-to-cellulose mass ratio, milling time, ball size and alkaline pretreatment were investigated. It was found that milling-ball size should be carefully selected for producing fibrous morphologies instead of particulates. Milling time and ball-to-cellulose mass ratio were also found important to control the fiber morphology. Alkali pre-treatment helped in weakening hydrogen bonds between cellulose fibrils and removing small particles, but with the risks of damaging the fibrous morphology. In a typical run, cellulose nanofiber with an average diameter of 100 nm was obtained using soft mechanical milling conditions using cerium-doped zirconia balls of 0.4–0.6 mm in diameter within 1.5 h without alkaline pretreatment.

Similar content being viewed by others

References

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polym 87(2):963–979

Abdul Khalil HPS, Davoudpour Y, Islam MN, Mustapha A, Sudesh K, Dungani R, Jawaid M (2014) Production and modification of nanofibrillated cellulose using various mechanical processes: a review. Carbohydr Polym 99:649–665

Abe K, Iwamoto S, Yano H (2007) Obtaining cellulose nanofibers with a uniform width of 15 nm from wood. Biomacromolecules 8(10):3276–3278

Abe K, Nakatsubo F, Yano H (2009) High-strength nanocomposite based on fibrillated chemi-thermomechanical pulp. Compos Sci Technol 69(14):2434–2437

Arbatan TL, Zhang X, Fang Y, Shen W (2012) Cellulose nanofibers as binder for fabrication of superhydrophobic paper. Chem Eng J 210:74–79

Azizi Samir MAS, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 6(2):612–626

Bhatnagar A, Sain M (2005) Processing of cellulose nanofiber-reinforced composites. J Reinf Plast Compos 24(12):1259–1268

Bodin A, Backdahl H, Risberg B, Gatenholm P (2007) Nano cellulose as a scaffold for tissue engineered blood vessels. Tissue Eng 13(4):885

Bondeson D, Mathew A, Oksman K (2006) Optimization of the isolation of nanocrystals from microcrystalline cellulose by acid hydrolysis. Cellulose 13(2):171–180

Brown AJ (1886) On an acetic ferment which forms cellulose. J Chem Soc Trans 49:432–439

Brown Jr MR, Czaja W, Jeschke M, Young DJ (2006) Multiribbon nanocellulose as a matrix for wound healing, US Patent App. 20,070/053,960

Corrêa A, de Morais Teixeira E, Pessan L, Mattoso L (2010) Cellulose nanofibers from curaua fibers. Cellulose 17(6):1183–1192

Czaja W, Krystynowicz A, Bielecki S, Brown JRM (2006) Microbial cellulose-the natural power to heal wounds. Biomaterials 27(2):145–151

Eichhorn SJ (2011) Cellulose nanowhiskers: promising materials for advanced applications. Soft Matter 7(2):303–315

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

Frey MW (2008) Electrospinning cellulose and cellulose derivatives. Polym Rev 48(2):378–391

Fukuzumi H, Saito T, Iwata T, Kumamoto Y, Isogai A (2008) Transparent and high gas barrier films of cellulose nanofibers prepared by tempo-mediated oxidation. Biomacromolecules 10(1):162–165

Henriksson M, Henriksson G, Berglund LA, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polymer J 43(8):3434–3441

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9(6):1579–1585

Hubbe MA, Rojas OJ, Lucia LA, Sain M (2008) Cellulosic nanocomposites: a review. BioResources 3(3):929–980

Iwamoto S, Nakagaito A, Yano H (2007) Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Applied Physics a-Materials Science & Processing 89(2):461–466

Jazaeri E, Zhang L, Wang X, Tsuzuki T (2011) Fabrication of carbon nanofiber by pyrolysis of freeze-dried cellulose nanofiber. Cellulose 18(6):1481–1485

Kim CW, Kim DS, Kang SY, Marquez M, Joo YL (2006) Structural studies of electrospun cellulose nanofibers. Polymer 47(14):5097–5107

Koch CC (1997) Synthesis of nanostructured materials by mechanical milling: problems and opportunities. Nanostruct Mater 9(1–8):13–22

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90(2):735–764

Moran JI, Alvarez VA, Cyras VP, Vazquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15:149–159

Nakagaito A, Yano H (2004) The effect of morphological changes from pulp fiber towards nano-scale fibrillated cellulose on the mechanical properties of high-strength plant fiber based composites. Appl Phys A Mater Sci Process 78(4):547–552

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose IÎ2 from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124(31):9074–9082

Nogi M, Yano H (2008) Transparent nanocomposites based on cellulose produced by bacteria offer potential innovation in the electronics device industry. Adv Mater 20(10):1849–1852

Recouvreux DOS, Rambo CR, Berti FV, Carminatti CA, Antônio RV, Porto LM (2011) Novel three-dimensional cocoon-like hydrogels for soft tissue regeneration. Mater Sci Eng, C 31(2):151–157

Sain M, Bhatnagar A (2008) Manufacturing process of cellulose nanofibers from renewable feed stocks. US Patent: US 2008/0146701 A1

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8(8):2485–2491

Segal L, Creely JJ, Martin AE, Conrad JR, Conard CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494

Tsuzuki T, Liyuan Z, Rana R, Qingtao L, Xungai W (2010) Production of green nanomaterials. In: Proceedings of the international conference on nanoscience and nanotechnology 2010, IEEE, pp 150–153

Wertz J, Schneiders I (2009) Filtration media: advantages of nanofiber coating technology. Filtr Sep 46(4):18–20

Ye DY (2007) Preparation of nanocellulose. Prog Chem 19:1568–1575

Zhang L, Tsuzuki T, Wang X (2010) Preparation and characterization on cellulose nanofiber film. Mater Sci Forum 654–656:1760–1763

Zhang L, Batchelor W, Varanasi S, Tsuzuki T, Wang X (2012) Effect of cellulose nanofiber dimensions on sheet forming through filtration. Cellulose 19(2):561–574

Zimmermann T, Bordeanu N, Strub E (2010) Properties of nanofibrillated cellulose from different raw materials and its reinforcement potential. Carbohydr Polym 79(4):1086–1093

Acknowledgments

Liyuan Zhang thanks IDP Education Australia Ltd. for the IDP Student Mobility Scholarship, Dr. Warren Batchelor for providing the standard pulp sample as starting materials, Deakin Microscopy Center for SEM imaging, Chuntao Zhang for helping with the experiments, Ruoyang Chen, Monash University and Hui He, Donghua University for helping with the figures, and Dr. Xu Li from Bio21 Institute, University of Melbourne, Dr. Tina Arbantan from Dulux Austrlia, Ltd., and Chenfan Xia, Deakin University, for proof reading the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Tsuzuki, T. & Wang, X. Preparation of cellulose nanofiber from softwood pulp by ball milling. Cellulose 22, 1729–1741 (2015). https://doi.org/10.1007/s10570-015-0582-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0582-6