Abstract

The fortification of gluten-free bread containing inulin with different organic and non-organic calcium sources was investigated. Calcium lactate, calcium citrate, calcium chloride and calcium carbonate were used as calcium sources. Gluten-free bread composed of corn starch, potato starch, salt, yeast, pectin, sugar and sunflower oil was used as a reference. The calcium salts were supplemented to the gluten-free formula to provide equal content of elementary calcium (Ca+2). The Mixolab® device was used to analyse the behaviour of gluten-free dough subjected to a dual mechanical shear stress and temperature constraint. Calcium salts significantly modified the dough behaviour during heating and cooling. The addition of calcium carbonate and calcium citrate provoked an increase in dough consistency during heating and cooling compared with the other salt-enriched samples. The specific volume and texture parameters of gluten-free breads varied with the calcium salt used, but calcium carbonate and calcium citrate showed improved values. The higher calcium content of the enriched breads, compared with the control, confirmed the fortification. Sensory evaluation of the calcium-fortified breads confirmed that calcium carbonate followed by calcium citrate was the most recommended salt for obtaining calcium fortification of gluten-free breads.

Similar content being viewed by others

Introduction

Serologic screening studies have shown that the worldwide prevalence of coeliac disease (CD) is to be 0.3–1.2 % in unselected European, North American, South American and Indian populations [1–3]. Such a rate establishes coeliac disease as one of the most common genetically based diseases. That acquired and permanent enteropathy is caused by wheat gliadins and other prolamins, like secalin of rye, hordein of barley and possibly avenin of oat [4]. In patients suffering from CD, the reaction followed by the consumption of gluten-containing products leads to a small intestinal mucosal inflammation. This proximal location in the small intestine often results in malabsorption of calcium, iron, folic acid and fat-soluble vitamins. Patients newly diagnosed or inadequately treated often have low bone mineral density, which appears to be directly related to the intestinal malabsorption. Osteomalacia or osteopenia are secondary to the reduced calcium absorption, caused by atrophy of the intestinal villi, and/or to a vitamin D deficiency, leading to secondary hyperparathyroidism [5]. Osteoporosis is therefore a frequent complication accompanying coeliac disease [6].

Strict and lifelong adherence to a gluten-free diet is the only proven treatment for coeliac disease; however, gluten-free diet is extremely difficult to adhere to due to the ubiquity of gluten in human foods. Besides, many gluten-free cereal products provide lower level of B vitamins (thiamine, riboflavin or niacin) [7], folate, iron and dietary fibre [8, 9] than their enriched wheat-based counterparts, they are intended to replace. These deficiencies appear to be due to the use of refined grains or starches and the relative lack of vitamins and minerals enrichment. Many studies related to gluten-free bakery products have been focused on the design of gluten-free matrix to overcome the negative impact on the absence of gluten network. Newly developed gluten-free formulas are composed of different starches, functional ingredients, additives, and pseudocereals to mimic the viscoelastic properties of gluten resulting in the improvement of the structure, mouthfeel, acceptability and shelf-life of gluten-free products [10–13].

Calcium has vital functions within cells in all living creatures, predominantly as a second messenger transmitting signals between the plasma membrane and the intracellular machinery. Extracellular calcium is also an essential cofactor in clotting factors and adhesion molecules and is essential for the proper formation of bones. Calcium deficiency is readily connected with osteoporosis, caused by a decreased of bone calcium content. Nutritional calcium deficiency may give rise to a number of so-called calcium paradox diseases (hypertension, arteriosclerosis, neurodegenerative diseases, malignancy, degenerative join diseases) caused by intracellular calcium overflow into soft tissue and intracellular compartment through the action of PTH [14], whereas a high calcium intake is suggested to prevent colorectal cancer [15] and decrease blood pressure and cholesterol level [16].

Calcium is an essential nutrient required in substantial amounts. In the UK, mandatory fortification of white flour with calcium carbonate contributes approximately 14 % of total calcium intake [17]. In Poland, the enrichment of flour and cereal products in calcium comes up to 3 g/kg of a product using mainly calcium carbonate [18]. Ranhotra et al. [19] have shown that flour can be fortified to contain Ca at high level without adversely affecting white gluten bread quality. Generally, gluten-free formulas and baked products are poor in minerals, including calcium [20, 21]. Calcium fortification of such products could increase the calcium content in the coeliac patients’ diet, allowing them to obtain the amount of calcium they need for prophylactic or therapeutic use. Many diets are deficient in calcium making supplementation necessary or desirable. Multiple forms of calcium supplements are available [22]. A variety of factors may impact the selection of a calcium supplement (e.g. medical conditions such as lactose intolerance, impaired gastric acid secretion and high-risk profile for kidney stone formation). Besides, the selection of the appropriate calcium salt for a specific food application should be based on the consideration of a number of properties associated with the respective product such as solubility, calcium content, taste and bioavailability. Calcium bioavailability depends on its chemical form and factors affecting its solubility. Low pH, basic amino acids, lactose, organic acids, bile salts and adequate calcium/phosphorus ratio increase calcium bioavailability, whereas higher pH, non-soluble dietary fibre, phytates and oxalates greatly reduce calcium absorption. Calcium supplements vary in calcium content with the largest per cent of calcium (40 %) in calcium carbonate (most cost-effective and readily available in some antacids), with other salts such as citrate, lactate and gluconate furnishing 21, 14 and 9.3 % of calcium, respectively [23]. Currently, the dominant anions in the calcium supplement market worldwide are carbonate and citrate [24]. It has been reported that calcium as citrate is better absorbed than calcium as carbonate, causing a greater rise in serum calcium and a greater fall in serum parathyroid hormone (PTH) [25, 26]. Moreover, calcium as citrate is absorbed regardless of gastric acidity; thus, persons producing less gastric acids or receiving drugs that lower acidity in the stomach, like proton pump inhibitors [27], H2 blockers, antacids and anticholinergics, may utilise this salt form optimally.

Prebiotics, such as inulin and oligofructose, are gaining more and more attention because they improve minerals absorption from the diet, bone mineral content (BMC) and bone structure [28, 29]. Oligosaccharides, which are non-digestible and not absorbed in the upper part of gastrointestinal track, enter large intestine, where they are fermented by the gut microbiota. As an effect of fermentation, the reduction in pH occurs as the result of stimulated production of lactic acid and short-chain fatty acids, mainly propionate, acetate and butyrate [30]. At lower pH, more mineral is soluble in the gut lumen and thus is more readily absorbed from the gut mucosa cell [31]. Apart from indirect stimulation of minerals absorption by increasing its solubility via lowering the pH, short-chain fatty acids can also directly influence its bioavailability by complexing with the minerals leading to an increase in their absorption. Inulin-type fructans (ITF, fructooligosaccharides and inulin) affect positively mineral bioavailability. Besides luminal pH reduction, their effect was accompanied by modifications in the architecture of the rat’s intestinal mucosa that arise as a consequence of the increase in cellularity and the number of crypts, mechanisms that could contribute to an increase in the absorptive surface for mineral uptake [32]. Younes et al. [33] analysing intestine fermentation of inulin and resistant starch in rats reported increased absorption and balance of Ca and Mg, without altering the plasma level of these two minerals. Inulin-type fructans added to the diet increased the retention of calcium in the whole body [34] and affects positively bones mineralisation [35, 36].

Mechanisms by which inulin and oligofructose influence calcium absorption have been already described [37, 38]. Conversely to wheat-containing products [39], very few gluten-free products are enriched in calcium. In this research, we focused on the technological characteristic of a new gluten-free baking product with inulin and calcium supplements addition. The aim of the study was to characterise the mixing and pasting behaviour of the experimental gluten-free bread with the Mixolab®, and to analyse the technological properties and overall quality of obtained calcium-fortified gluten-free breads with inulin.

Materials and methods

Ingredients

In this study, a previously optimised gluten-free formula [40] was slightly modified, namely 3.9 % of corn starch was substituted by inulin (Hortimex, Konin, Poland) and used as a control. Because the ingredients of gluten-free bread varied greatly from those of cereal bread, the guidelines for calcium supplements of cereal bread may not be suitable for gluten-free bread. For this reason, series of calcium supplements were tested instead of the dominant anions in the calcium supplements market worldwide, such as carbonate and citrate [24]. Among available calcium supplements, four calcium salts were applied: two organic: calcium citrate (21.1 % calcium according to the manufacturer (E 333(iii), Hortimex, Konin, Poland) and calcium lactate (11–14 % calcium according to the manufacturer, E 327, Hortimex, Konin, Poland); and two inorganic: calcium carbonate (40 %, No. 878330111, POCH, Gliwice, Poland) and calcium chloride (27.2 %, No. 874930111, POCH, Gliwice, Poland). The investigated calcium salts were incorporated into the gluten-free formula as supplements to provide the same content of elementary calcium (0.6 g/100 g Ca+2) [41]. Salt, sugar, fresh yeast (Drożdże Babuni, Lesaffre S.A, Wołczyn, Poland) and sunflower oil (ZPT, Warsow, Poland) were purchased in the local market.

Mixolab® measurements

Mixing and pasting behaviour of gluten-free dough with inulin fortified with different calcium salts was studied using Mixolab® (Chopin, Tripette et Renaud, Paris, France), which measured at real time the torque (expressed in Nm) produced by passage of dough between the two kneading arms, thus allowed the study of its physico-chemical behaviour [42]. For the assays, 90 g of experimental gluten-free formulas fortified with different calcium salts, without the addition of yeast and oil, were placed into the Mixolab® bowl and mixed. A constant amount of water was added. The settings used for the test were 15 min for initial mixing at 30 °C, temperature increase of 4 °C/min until 90 °C, 8 min holding at 90 °C, temperature decrease of 4 °C/min until 50 °C, 2 min holding at 50 °C, and the mixing speed during the entire assay was 80 rpm. Dough consistency curves were recorded. The duration of each assay was 50 min. Detailed description of the physical changes that occurred along Mixolab® measurement was reported by Rosell et al. [42].

Breadmaking process

Potato starch (178 g), inulin (78 g) and pectin (44 g) were added successively to corn starch (656 g) and mixed, then calcium supplement (amount calculated for each salt to provide 0.6 % of Ca2+) was added and all solid ingredients were mixed together for 5 min at minimum speed using a KitchenAid Professional K45SS mixer (KitchenAid Europa, Inc, Brussels, Belgium) in the stainless steel bowl with flat beater. Subsequently, sugar (56 g), fresh yeast (56 g) and salt (16 g), previously dissolved separately in deionised water (888 ml), were added to the dry mixture together with oil (28 g). The batter was mixed for 12 min. A 240-g sample of the resulting batter was placed in a rectangular greased baking tins (70 × 90 mm) and rested in a proofer at 35 °C and 70 % relative humidity for 40 min. Baking was then carried out for 30 min at 220 °C in the laboratory oven previously steamed (SVEBA DAHLEN, AB model DC-21, Sweden). After baking, the breads were removed from the pans and cooled to room temperature (2 h). Nine loaves were baked form each formula. Experimental breads were divided into two groups. First part was analysed directly after cooling. The size-related parameters, crumb colour and texture of fresh bread were analysed. The other part was packed in a clip-on polyethylene bag and stored for 24 h at ambient temperature (22 ± 2 °C) for crumb texture analysis after storage and semi-consumer test.

Bread evaluation

In order to determine the bread quality, three breads of each formula were analysed. Loaf weight (using a digital balance with 0.01-g accuracy), volume (millet seeds displacement method) and moisture content [43] were evaluated. Values obtained were the mean of three replicates. The specific volume (ratio of volume and weight) and bake loss, defined as the amount of water and organic material lost during baking, were calculated. Scans of the example slice of each experimental gluten-free bread were made using a flatbed scanner (Epson Perfection V200 Photo) supported by Epson Creativity Suite Software Images.

Instrumental colour analysis

The instrumental measurement of the bread crumb colour was quantified using a HunterLab ColorFlex (Hunter Associates Laboratory, Inc, Virginia, USA), and the results were expressed in accordance with the CIELAB system with reference to illuminant D65 and a visual angle of 10°. The measurements were performed through a 3-cm-diameter diaphragm containing an optical glass. The parameters determined were L* (L* = 0 [black] and L* = 100 [white]), a* (–a* = greenness and +a* = redness), and b* (–b* = blueness and +b* = yellowness). Values were the mean of nine replicates.

Texture properties

The texture profile (TPA test) [44] of fresh and 24-hour-stored bread crumbs was analysed using texture analyser TA.HDPlus with TPA Exponent Software (Stable Micro Systems Ltd., Surray, UK) equipped with a 30-kg load cell. The middle bread slices of 25-mm-thickness underwent a double compression cycle up to 40 % deformation of its original height with a 35-mm flat-end aluminium compression disc (probe P/35). The selected settings were as follows: pretest/test/posttest speed, 2.0 mm/s; relaxation time, 5 s; force, 10 g; trigger, mode auto. Eight replicates were analysed for each kind of bread and storage time. The bread was compressed twice to give a two-bite texture profile curve [44], from which four textural parameters were obtained: hardness, springiness, cohesiveness and chewiness as calculated by the software of the texturometer [45].

Sensory evaluation

Thirty-six non-trained testers (24 females and 12 male, ranging in age between 24 and 62) made hedonic evaluation of the acceptability of gluten-free bread samples using a nine-point hedonic scale (1 = unacceptable, 9 = very acceptable) [46, 47]. In the test, participants were asked about their preference concerning experimental gluten-free bread.

Calcium determination

The calcium determination was done in freeze-dried gluten-free doughs and breads. The measurement of calcium content in calcium salts was carried out using the atomic absorption spectroscopy (AAS) method by a Unicam 939 spectrometer equipped with data basis ADAX, background correction and cathode lamps. Before determination, all samples were wet mineralised with a mixture of nitric (cat. No 1004562500, Merck, USA) and perchloric (cat. No 1005192501, Merck, USA) acids (3:1; v/v) [48]. Values were the mean of three replicates.

Statistical analysis

The results were analysed using the statistical program Statgraphics Centurion XV (StatPoint Inc., Virginia, USA). Fisher’s least-significant differences test was used to define differences between means at the 5 % significance level (P < 0.05).

Results and discussion

Effect of the addition of calcium salts on the gluten-free dough behaviour

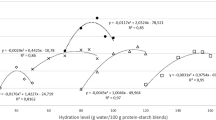

The Mixolab® was used for recording the gluten-free dough behaviour during mixing–heating–cooling. Therefore, changes associated with dough during mixing due to ingredients hydration, together with starch gelatinisation and starch gelling, were registered by following dough consistency [49]. Generally, gluten-free dough supplemented with calcium salts followed the same consistency trend during mixing–heating–cooling as the control dough. Nevertheless, during the mixing stage great differences were induced by the addition of calcium salts, and the extent of the effect on the dough consistency was dependent on the calcium salt source (Fig. 1). The supplementation of gluten-free dough with calcium lactate or calcium chloride resulted in a significant decrease in the dough consistency during mixing. In opposition, calcium citrate promoted an increase in the dough consistency. Likely, the chemical structure of the salt modified the water absorption of the starch granules of corn and potato. No effect was detected on the pasting formation, with the exception of calcium lactate that delayed the gelatinisation process.

Effect of calcium salts on the gluten-free dough consistency determined by Mixolab® device. CAR gluten-free bread fortified with calcium carbonate, CHL gluten-free bread fortified with calcium chloride, CIT gluten-free bread fortified with calcium citrate and LAC gluten-free bread fortified with calcium lactate

Regarding the heating–cooling cycle, two different slopes were detected in the Mixolab® curve corresponding to the gelatinisation of the two types of starch (potato and corn) (Fig. 1). The first slope was detected around 28–31 min, whereas the second one was observed from 31 to 36 min. The individual analysis of each type of starch allowed identifying the first slope as potato starch gelatinisation and the second one corresponded to corn starch gelatinisation. Matos and Rosell [50] described that different peaks were detected in the Mixolab when using different starches due to their diverse pasting temperatures, being 65.4 °C for potato starch, 69.9 °C for corn starch and 70.2 °C for rice flour. Supplementation of gluten-free dough with calcium salts modified the gelatinisation behaviour of the corn starch, as indicated by the delay in the onset of the second peak that appeared between 30 and 37 min, without affecting the potato starch. Presumably, potato starch, which swells in first place, was not affected because its gelatinisation was not water limited, but the gelatinisation process of the corn starch was hindered by some salts (chloride and lactate) with higher ability to hold water. Several studies have reported that the starch gelatinisation is modified by the addition of salts and that process is dependent on the type of salt. In fact, Jane [51] reported that salts, namely the anion, modify the equilibrium between the structure-making and structure-breaking effects of water, and also the electrostatic interactions between salts and hydroxyl groups of starch. Citrate and carbonate led to a large increase in the dough consistency during heating. Presumably, those salts favoured the corn starch swelling resulting in a very high maximum consistency during heating. Conversely, lactate and chloride induced the opposite effect, resulting in delayed corn starch swelling, and calcium chloride lowered the maximum consistency reached. During the cooling process, an enhancement of dough consistency associated with starch gelling, due to amylose chains crystallisation, was observed. That consistency increase is greatly dependent on the starch type and the presence of gelling additives or ingredients with water binding ability [42, 52]. A high increase in the consistency during cooling suggests that dough presents high retrogradation tendency, and consequently, the baked product prepared from this dough would undergo high staling rate over storage [50]. Differences observed in the dough consistency at cooling (consistency at the end of the test) in the presence of different salts suggest that anions not only modified the starch gelatinisation, but also the starch chains’ recrystallisation. Calcium chloride led to the lowest difference of consistency between 90 and 50 °C; thus, it was the salt that reduced the retrogradation of the starch during cooling. This result agrees with Baker and Rayas-Duarte [53] that stated the effect of salts and sugars on the retrogradation of starches from different sources. Those authors found that sodium chloride reduced the retrogradation of starches during storage. Therefore, the addition of calcium salts to a gluten-free formulation modifies the dough performance during mixing–heating–cooling, which could have a great impact on the resulting gluten-free bread.

Calcium content determination

Calcium supplements vary in calcium content with the largest per cent in calcium carbonate, furnishing 40 % of calcium [23]. Among calcium supplements analysed in this study, the highest calcium content was determined in calcium carbonate, followed by calcium chloride, citrate and lactate (Table 1). As it was expected, the supplementation of experimental gluten-free formula with calcium salts increased the calcium content in fortified doughs and breads. Since the amount of calcium salts incorporated into the experimental formulas provided 0.6 g/100 g of elementary Ca+2, no statistically significant differences were observed among analysed doughs or breads fortified with different calcium salts. Analysed gluten-free doughs and breads were significantly richer in calcium in comparison with unfortified controls. Good food sources provide approximately 100–190 mg of calcium and contribute at least 10-19 % of the daily value (DV) for calcium, whereas excellent sources of calcium are considered to provide at least 20 % DV of calcium [54]. The examined fortified gluten-free breads provided more than 10 mg/g; therefore, according to WHO [55] they could be considered as an excellent source of calcium.

Bread evaluation

The values obtained for moisture content, specific volume, bake loss and crumb colour are presented in Table 2. Compared with the control bread, calcium supplements generally did not affect the moisture content of analysed gluten-free breads; however, in the case of bread containing calcium citrate (CIT), the moisture increased significantly. Compared with our previous study on gluten-free bread without inulin [40], a rise of the specific volume of the analysed control gluten-free bread was observed, probably due to inulin addition to the formulation. Inulin thoroughly mixed with water or another aqueous liquid forms a gel composed of a tri-dimensional network of insoluble sub-micron crystalline inulin particles in water [56]. Large amounts of water are immobilised in this network, which assures its physical stability. Korus et al. [57] analysing the influence of different prebiotics on gluten-free bread indicated that high doses of inulin (5 and 8 %) increased the volume of gluten-free bread by about 4 and 9 %, compared with the control, respectively. Compared with the control bread, the addition of analysed calcium salts to the experimental gluten-free formulation did not affect the specific volume of breads, with the exception of bread with calcium lactate (LAC), where a significant reduction in the specific volume was observed. Calcium supplements are used as preservatives, and firming agents are used in fresh and minimally precessed fruits and vegetables in order to strength the structure of the food product and enhance its firmness [58, 59]. Calcium is involved in maintaining the textural quality of produce since calcium ions form cross-links or bridges between free carboxyl groups of the pectin chains, resulting in the strengthening of the cell wall [60].

The influence of calcium supplements on the bake loss was diverse (Table 2). Calcium carbonate or calcium citrate addition to experimental breads did not change significantly the amount of water and organic material lost during baking (14.94 and 14.09 %, respectively). The opposite effect was observed in breads with CHL and LAC, where in comparison with the control, the value of bake loss was significantly reduced by those calcium supplements. In both cases, the breads crumb was also characterised by the smallest pore size (Fig. 2c, e). Roca et al. [61] suggested that crumb morphology strongly affects the rate of water transport. Smaller pore size is expected to slow down the moisture migration [62]. Besides, increasing number of connections between each gas cells with increased size of gas cells [63] may also influence the rate of water transport. Therefore, the differences in bake loss observed between calcium-fortified breads may result from the size of pores (Table 2; Fig. 2).

Scans of the example slice of gluten-free breads with inulin fortified with different calcium salts. a Unfortified control, b gluten-free bread fortified with calcium carbonate (CAR), c gluten-free bread fortified with calcium chloride (CHL), d gluten-free bread fortified with calcium citrate (CIT) and e gluten-free bread fortified with calcium lactate (LAC)

The addition of calcium supplements affected the colour of crumb of gluten-free breads (Table 2; Fig. 2). In most cases, significant differences were observed between unfortified control and the fortified samples as well as among all gluten-free breads with different calcium supplements. Regarding the crumb colour, the highest values of lightness (L*) were observed in the control bread (71.55), while the crumb of gluten-free bread with calcium salts was darker. The L* value decreased gradually in breads containing calcium chloride or calcium citrate, followed by crumbs of bread containing calcium lactate; finally, the crumb of bread supplemented with calcium carbonate was the darkest. Among the calcium supplements used in the experimental breads, only calcium carbonate is recognised as food colourant [64]. However, surprisingly the colour of calcium carbonate (white) did not confer the light colour of bread CAR crumb. Nevertheless, lightness values were higher than the ones reported by Marco and Rosell [49] with gluten-free rice-based breads, likely due to the starch composition of the breads obtained in the present study. In all analysed crumb samples, the value of parameter a* was positive (red hue), however, rather low. Regarding the unfortified control, the incorporation of calcium lactate or chloride to gluten-free bread affected the significant increase in crumb redness (P ≤ 0.05). This effect was especially visible in the case of bread LAC where the a* value was two times higher than in the control. Inversely, in bread CIT and CAR, a decrease in redness was observed. The b* values detected for all crumbs were also positive (yellow hue). In comparison with the crumb of the control bread, the addition of calcium lactate and chloride increased the crumb yellowness, whereas calcium carbonate reduced the b* value.

Texture analysis

The texture profile including hardness, springiness, cohesiveness and chewiness of fresh and 24-hour-stored gluten-free bread with calcium salts is presented in Table 3. Bread CHL containing calcium chloride showed the highest hardness. In comparison with the fresh control bread, the addition of calcium carbonate or calcium lactate did not influence significantly the crumb hardness, whereas calcium citrate decreased significantly the hardness of the bread crumb. Most of the analysed calcium salts improved basically the crumb springiness and cohesiveness, and only in the case of bread with calcium chloride both mentioned texture properties were similarly low as in the control. Springiness is associated with a fresh and elastic product; therefore, high-quality bread will be related to high springiness values. Cohesiveness characterises the extent to which a material can be deformed before it ruptures, reflecting the internal cohesion of the material. Bread with high cohesiveness is desirable because it forms a bolus rather than disintegrates during mastication, whereas low cohesiveness indicates increased susceptibility of the bread to fracture or crumble [65]. With the exception of calcium chloride, the addition of calcium salts improved the cohesion in the crumb internal structure. The analysis of chewiness, which is a product of hardness, springiness and cohesiveness, showed that the crumb of fresh control bread was characterised by the lowest value of chewiness. Chewiness is related to the time required masticating a bread piece prior to swallow, and low chewing value means easy break of the bread in the mouth. The utilisation of calcium salts in gluten-free formulations resulted in a significant increase in chewiness of fresh bread crumbs. Among analysed samples of gluten-free bread crumbs, the crumb of bread with calcium chloride (CHL) was characterised with the highest values of chewiness.

The storage time influenced the texture properties of examined breads, especially the crumb hardness (Table 3). After 24 h, the crumb of all breads was much harder in comparison with fresh bread crumbs. The hardness of stored bread containing calcium chloride was the highest. Other examined breads were much softer; however, only in case of bread CAR, its hardness was significantly lower than the one of the control. Bread containing calcium carbonate was also characterised with the highest springiness. Stored gluten-free breads were generally less cohesive than fresh ones; however, similarly like in the case of fresh breads, calcium supplements influence positively the cohesiveness of stored bread crumbs. Storage increases the chewiness of bread crumb, with the exception of the stored bread CIT, where the values obtained were even lower than in the fresh CIT bread.

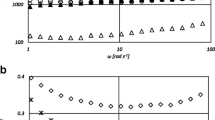

Sensory evaluation

Participants of the sensory evaluation perceived analysed control bread as tasty and sweet, and gave high scores (Fig. 3). Korus et al. [57] indicated that the addition of inulin caused an increase in the sugar content of gluten-free bread. The hydrolysis of inulin by different strains of yeasts is common [66] and results in the fructose formation. The calcium compounds affected the overall preferences of gluten-free breads in a different manner. Some calcium salts had a positive effect while others had a negative effect on the tastiness of experimental breads. Consumers decided that bread CAR fortified with calcium carbonate was the most acceptable one and that it had the significantly better quality than the control. Among analysed gluten-free breads with calcium supplement, bread CAR was the most promising, indicating that calcium carbonate might contribute to improving the sensory characteristics of gluten-free bread. Bread with calcium citrate obtained scores similar to the control. While gluten-free bread with calcium lactate or calcium chloride received the lowest scores (lower than 2), corresponding to an unacceptable quality with no desirable characteristic. Such low scores received by bread LAC and CHL resulted from their poor taste, that was defined by consumers as bitter, and their sticky texture was described as ‘sadness cake’.

Overall preference of gluten-free bread fortified with calcium salts. Bars labelled with different letters are significantly different (P ≤ 0.05). CAR gluten-free bread fortified with calcium carbonate, CHL gluten-free bread fortified with calcium chloride, CIT gluten-free bread fortified with calcium citrate and LAC gluten-free bread fortified with calcium lactate

Conclusions

The current research has shown the possibility to obtain good-quality gluten-free bread with inulin enriched with calcium. All experimental breads were significantly richer in calcium than the control one. Calcium carbonate and calcium citrate were the salts that induced an increase in dough consistency during heating and cooling; thus, this dough trend should be recommended for obtaining good-quality gluten-free breads. Among the applied calcium supplements, the most beneficial effect on bread technological properties was found for calcium carbonate. Bread CAR was characterised with the highest value of specific volume, its crumb was softer and more springier in comparison with the control crumb. Besides, bread containing calcium carbonate was distinguished by consumers. In vivo studies on bioavailability of calcium from fortified gluten-free bread containing inulin will be undertaken to assess the efficiency of calcium absorption.

References

Fasano A, Berti I, Gerarduzzi T, Not T, Colletti RB, Drago S, Elitsur Y, Green PH, Guandalini S, Hill ID, Pietzak M, Ventura A, Thorpe M, Kryszak D, Fornaroli F, Wasserman SS, Murray JA, Horvath K (2003) Prevalence of celiac disease in at-risk and not-at-risk groups in the United States: a large multicenter study. Arch Int Med 163:286–292

Tommasini A, Not T, Kiren V, Baldas V, Santon D, Trevisiol C, Berti I, Neri E, Gerarduzzi T, Bruno I, Lenhardt A, Zamuner E, Spanò A, Crovella S, Martellossi S, Torre G, Sblattero D, Marzari R, Bradbury A, Tamburlini G, Ventura A (2004) Mass screening for coeliac disease using anti-human transglutaminase antibody assay. Arch Dis Child 89:512–515

Sampson M, Zhang L, Yazdi F, Mamaladze V, Pan I, McNeil J, Mack D, Patel D, Moher D (2005) The prevalence of coeliac disease in average-risk and at-risk Western European populations: a systematic review. Gastroenterol 128:57–67

Vader LW, Stepniak DT, Bunnik EM, Kooy YM, de Haan W, Drijfhout JW, Van Veelen PA, Konig F (2003) Characterization of cereal toxicity for coeliac disease patients based on protein homology in grains. Gastroenterol 125:1105–1111

Selby PL, Davies M, Adams JE, Mawer EB (1999) Bone loss in celiac disease is related to secondary hyperparathyroidism. J Bone Min Res 14:652–657

Meyer D, Stavropolous S, Diamond B, Shane E, Green PHR (2001) Osteoporosis in a North American adult population with celiac disease. Am J Gastroenterol 96:112–119

Thompson T (1999) Thiamin, riboflavin, and niacin contents of the gluten-free diet: is there cause for concern? J Am Diet Assoc 99:858–862

Thompson T (2000) Folate, iron, and dietary fiber contents of the gluten-free diet. J Am Diet Assoc 100:1389–1396

Matos ME, Rosell CM (2011) Chemical composition and starch digestibility of different gluten free breads. Plant Food Hum Nutr 66:224–230. doi:10.1007/s11130-011-0244-2

Gallagher E, Gormley TR, Arendt EK (2003) Crust and crumb characteristics of gluten free breads. J Food Eng 56:153–161

Gujral HS, Rosell CM (2004) Improvement of the breadmaking quality of rice flour by glucose oxidase. Food Res Int 37:75–81

Ahlborn GJ, Pike OA, Hendrix SB, Hess WM, Huber CS (2005) Sensory, mechanical, and microscopic evaluation of staling in low-protein and gluten-free breads. Cereal Chem 82:328–335

Rosell CM (2009) In: Gallagher E (ed) Gluten-free food science and technology. Wiley-Blackwell Publishing Ltd, Oxford

Fujita T (2000) Calcium paradox: consequences of calcium deficiency manifested by a wide variety of disease. J Bone Miner Metab 18:234–236

Wu K, Willett WC, Fuchs CS, Colditz GA, Giovannucci EL (2002) Calcium intake and risk of colon cancer in women and men. J Natl Cancer Inst 94(6):437–446

Bell L, Halstenson CE, Halstenson CJ, Macres M, Keane WF (1992) Cholesterol-lowering effects of calcium carbonate in patients with mild to moderate hypercholesterolemia. Arch Intern Med 152(12):2441–2444

Department of Health (1998) Report on health and social subjects. No. 49. Nutrition and bone health with particular reference to calcium and vitamin D. HMSO, London

Gawęcki J, Hryniewiecki L (1998) Żywienie człowieka. Podstawy nauki o żywieniu. Wydawnictwo Naukowe PWN Warsow (in Polish)

Ranhotra GS, Gelroth JA, Leinen SD (1999) Increase in bone calcification in young rats fed breads highly fortified with calcium. Cereal Chem 67:325–327

Wronkowska M, Troszyńska A, Soral-Śmietana M, Wołejszo A (2008) Effects of buckwheat flour (Fagopyrum esculentum moench) on the quality of gluten-free bread. Pol J Food Nutr Sci 58:211–216

Krupa-Kozak U, Wronkowska M, Soral-Śmietana M (2011) The effect of buckwheat flour on microelements and proteins content in gluten-free bread. Czech J Food Sci 29:103–108

Fishbain L (2004) Multiple source of dietary calcium—some aspects of its essentiality. Regul Toxicol Pharmacol 39:67–80

Berdanier GD (2002) Handbook of nutrition. CRC Press, Boca Raton

Recker RR, Heaney RP (2001) The role of combination treatment for osteoporosis. J Clin Endocrinol Metabol 86:1888–1889

Thomas SDC, Need AG, Tucker G, Slobodian P, O’Loughlin PD, Nordin BEC (2008) Suppression of parathyroid hormone and bone resorption by calcium carbonate and calcium citrate in postmenopausal women. Calcified Tissue Int 83:81–84

Tondapu P, Provost D, Adams-Huet B, Sims T, Chang C, Sakhaee K (2009) Comparison of the absorption of calcium carbonate and calcium citrate after Roux-en-Y gastric bypass. Obes Surg 19:1256–1261

O’Connell MB, Madden DM, Murray AM, Heaney RP, Kerzner LJ (2005) Effects of proton pump inhibitors on calcium carbonate absorption in women: a randomized crossover trial. Am J Med 118:778–781

Harrington ME, Flynn A, Cashman KD (2001) Effects of dietary fibre extracts on calcium absorption in the rat. Food Chem 73:263–269

Scholz-Ahrens K, Schrezenmeir J (2007) Inulin and oligofructose and mineral metabolism: the evidence from animal trials. J Nutr 137:2513–2523

Levrat MA, Remesy C, Demigne C (1991) High propionic acid fermentations and mineral accumulation in the cecum of rats adapted to different levels of inulin. J Nutr 121:1730–1737

Ohta A, Ohtsuki M, Baba S, Adachi T, Sakata T, Sakaguchi EI (1995) Calcium and magnesium absorption from the colon and rectum are increased in rats fed fructooligosaccharides. J Nutr 125:2417–2424

Kleessen B, Hartmann L, Blaut M (2003) Fructans in the diet cause alterations of intestinal mucosal architecture, released mucins and mucosa-associated bifidobacteria in gnotobiotic rats. Brit J Nutr 89:597–606

Younes H, Coudray C, Bellanger J, Demigne C, Rayssiguier Y, Remesy C (2001) Effects of two fermentable carbohydrates (inulin and resistant starch) and their combination on calcium and magnesium balance in rats. Brit J Nutr 86:479–485

Raschka L, Daniel H (2005) Diet composition and age determine the effects of inulin-type fructans on intestinal calcium absorption in rat. Europ J Nutr 44:360–364

Zafar TA, Weaver CM, Zhao Y, Martin BR, Wastney ME (2004) Nondigestible oligosaccharides increase calcium absorption and suppress bone resorption in ovariectomized rats. J Nutr 134:399–402

Bosscher D, Van Loo J, Franck A (2006) Inulin and oligofructose as functional ingredients to improve bone mineralization. Int Dairy J 16:1092–1097

Scholz-Ahrens E, Schrezenmeir J (2002) Inulin, oligofructose and mineral metabolism-experimental data and mechanism. Brit J Nutr 87:179–186

Weaver CM (2005) Inulin, oligofructose and bone health: experimental approaches and mechanisms. Brit J Nutr 93:99–103

Martin BR, Weaver CM, Heaney RP, Packard PT, Smith DL (2002) Calcium absorption from three salts and CaSO4-fortified bread in premenopausal women. J Agric Food Chem 50:3874–3886

Krupa-Kozak U, Troszyńska A, Bączek N, Soral-Śmietana M (2011) Effect of organic calcium supplements on the technological characteristic and sensory properties of gluten-free bread. Eur Food Res Technol 232:497–508

Krupa U, Soral-Śmietana M, Wronkowska M (2008) Mieszanka bezglutenowa (eng. Gluten free mixture) Polish patent specification No P 386253

Rosell CM, Collar C, Haros M (2007) Assessment of hydrocolloid effects on the thermo-mechanical properties of wheat using the Mixolab®. Food Hydrocoll 21:452–462

American Association of Cereal Chemists (1995) Approved methods of the AACC, 9th ed. Method 44-19. The Association: St. Paul MN

Bourne MC (1978) Texture profile analysis. Food Technol 7:62–66

Gámbaro A, Giménez A, Ares G, Gilardi V (2006) Influence of enzymes on the texture of brown pan bread. J Texture Stud 37:300–314

Peryam DR, Pilgrim FJ (1957) Hedonic scale method of measuring food preferences. Food Technol 11(9):9–14

Baryłko-Pikielna N, Matuszewska I (2009) Sensoryczne badania żywności. Podstawy-Metody-Zastosowania. Wydawnictwo Naukowe PTTŻ Kraków 267–297 (in Polish)

Whiteside P, Miner B (1984) Pye Unicam atomic absorption data book. Pye Unicam LTD, Cambridge

Marco C, Rosell CM (2008) Breadmaking performance of protein enriched, gluten-free breads. Eur Food Res Technol 227:1205–1213

Matos ME, Rosell CM (2012) Quality indicators of rice based gluten-free bread-like products: relationships between dough rheology and quality characteristics. Food Bioprocess Technol. doi:10.1007/s11947-012-0903-9

Jane JL (1993) Mechanism of starch gelatinization in neutral salt-solutions. Starch-Starke 45:161–166

Rosell CM, Santos E, Collar C (2010) Physical characterization of fiber-enriched bread doughs by dual mixing and temperature constraint using the Mixolab ® Eur Food Res. Technol 231(4):535–544

Baker LA, Rayas-Duarte P (1998) Retrogradation of amaranth starch at different storage temperatures and the effects of salt and sugars. Cereal Chem 75:308–314

USDA (2001) Nutrient value of food. Publ. HG-7. US Department of Agriculture, Washington, DC, Available from http://www.nal.usda.gov/fnicfoodcomp

Human Vitamin and Mineral Requirements (1998) Draft report of a join FAO/WHO expert consultation. Bangkok, Thailand, September. World Health Organization, Geneva, pp 151–179

Franck A (2002) Technological functionality of inulin and oligofructose. Brit J Nutr 87(2):287–291

Korus J, Grzelak K, Achramowicz K, Sabat R (2006) Influence of prebiotics addition on the quality of gluten-free bread and on the content of inulin and fructooligosaccharides. Food Sci Technol Int 12:489–495

Manganaris GA, Vasilakakis M, Diamantidis G, Mignani I (2007) The effect of postharvest calcium application on tissue calcium concentration, quality attributes, incidence of flesh browning and cell wall physicochemical aspects of peach fruits. Food Chem 4:1385–1392

Luna-Guzman I, Barrett DM (2000) Comparison of calcium chloride and calcium lactate effectiveness in maintaining shelf stability and quality of fresh-cut cantaloupe. Postharv Biol Technol 19:61–72

Garcia JM, Herrera S, Morilla A (1996) Effects of postharvest dips in calcium chloride on strawberry. J Agric Food Chem 44:30–33

Roca E, Guillard V, Guilbert S, Gontard N (2006) Moisture migration in a cereal composite food at high water activity: effects of initial porosity and fat content. J Cereal Sci 43:144–151

Labbuza TP, Hyman CR (1998) Moisture migration and control in multi-domain foods. Trends Food Sci Technol 9:47–55

van Dalen G, Notenboom P, van Vliet LJ, Voortman L, Esveld E (2007) 3-D imaging analysis and modelling of porous cereal products using X-ray microtomography. Image Anal Stereol 26:169–177

Available form http://www.food-info.net

Onyango C, Mutungi C, Unbehend G, Lindhauer MG (2011) Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT Food Sci Technol 44:681–686

Mitterdorfer G, Kneifel W, Viernstain H (2001) Utilization of prebiotic carbohydrates by yeasts of therapeutic relevance. Lett Appl Microbiol 33:251–255

Acknowledgments

This work was partly supported by the National Science Centre, project DEC-2011/01/D/NZ9/02692 and Spanish Ministerio de Ciencia e Innovación (Project AGL2011-23802) and the Consejo Superior de Investigaciones Científicas (CSIC). The authors thank PhD Tomasz Jeliński for help in bread texture analysis.

Conflict of interest

The authors declare that there is no conflict of interest to disclose.

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Krupa-Kozak, U., Altamirano-Fortoul, R., Wronkowska, M. et al. Breadmaking performance and technological characteristic of gluten-free bread with inulin supplemented with calcium salts. Eur Food Res Technol 235, 545–554 (2012). https://doi.org/10.1007/s00217-012-1782-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-012-1782-z