Abstract

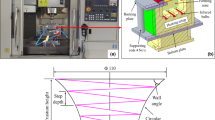

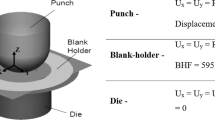

Residual stresses in metallic components greatly affect the geometrical accuracy of advanced high-strength steels (AHSS) products used for automotive industry. Chain-die forming is a promising method to fabricate AHSS products which can minimize the residual stress induced. This paper aims to understand the residual stress in chain-die-formed dual-phase (DP) steels through analytical and numerical modelling together with experimental validation. Analytical and numerical models were firstly employed to predict the stress development and associated residual stresses induced by chain-die forming in consideration of an as-received residual stress field and a comprehensive material-hardening model. The residual stresses in different regions of formed parts were practically measured using the neutron diffraction method to verify the developed models. Same as the mesh size of the examining points of finite element analysis (FEA) models, the averaged over the same sampling size is measured to guarantee the accuracy. It seems to be consistent with the simulation and experimental results in consideration of both factors. However, compared with as-received residual stress, the kinematic factor has a more dominating impact on the final residual stress. The results presented should contribute to the prediction of geometric errors and minimize product defects caused by the residual stresses in chain-die forming or equivalent sheet metal-forming industry.

Similar content being viewed by others

REFERENCES

Volden L, Gundersen Ø, Rørvik G (1999) Development of residual stresses in high strength low alloy steel, ISOPE-I-99-364, in The Ninth International Offshore and Polar Engineering Conference, International Society of Offshore and Polar Engineers, 30 May–4 June, Brest, France

Xu W, Burdekin F (1998) Effects of residual stresses on constraint and fracture behaviour of wide plates, in Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences, 1998, vol 454. The Royal Society, London, pp. 2505–2528

Ding S, Zhang Y, (2012) Chain-die Forming, is it a right forming method to make structural parts of motor vehicles with UHSS material, in Proceedings of International Conference on Advanced Vehicle Technologies and Integration (VTI 2012) pp.1–6

Sun Y, Li Y, Li D, Meehan PA, Daniel WJ, Shi L et al (2019) Predictive modelling of longitudinal bow in chain-die formed AHSS profiles and its experimental verification. J Manuf Process 39:208–225

Huang L, Chen X, Yu D, Chen Y, An K, (2018) Residual Stress Distribution in a Hydroformed Advanced High Strength Steel Component: Neutron Diffraction Measurements and Finite Element Simulations, SAE Technical pp 0148–7191

Deole AD, Barnett MR, Weiss M, (2018) The numerical prediction of ductile fracture of martensitic steel in roll forming, International Journal of Solids and Structures, vol 144. pp 20–31

Li Y, Sun Y, Xiao H, Bong HJ, Shi L, Li S et al (2018) A numerical study on chain-die forming of the AHSS U-channel and contrast with roll forming. Int J Mech Sci 135:279–293

Weiss M, Wolfkamp H, Rolfe B, Hodgson P, Hemmerich E, (2009) Measurement of bending properties in strip for roll forming, in Proceedings of International Deep Drawing Research Group, DKMBS Levy, CJ Van Tyne, Editor, Golden, CO, USA, 1–3 June

Abvabi A, Rolfe B, Hodgson P, Weiss M (2015) The influence of residual stress on a roll forming process. Int J Mech Sci 101:124–136

Abvabi A, Rolfe B, Hodgson P, Weiss M (2016) An inverse routine to predict residual stress in sheet material. Mater Sci Eng A 652:99–104

Abvabi A, (2014) Effect of residual stresses in roll forming process of metal sheets, PhD thessis, Deakin University, 2014

Weiss M, Rolfe B, Hodgson PD, Yang C (2012) Effect of residual stress on the bending of aluminium. J Mater Process Technol 212:877–883

Smith D, Bourke M, Hodgson A, Webster G, Webster P (1992) Interpretation of residual stress distributions in previously loaded cracked beams. J Strain Anal Eng Des 27:77–83

Mehner T, Bauer A, Härtel S, Awiszus B, Lampke T (2018) Residual-stress evolution of cold-rolled DC04 steel sheets for different initial stress states. Finite Elem Anal Des 144:76–83

Hundy B (1955) Determination of residual stresses in lightly rolled thin strip. J Iron Steel Inst 179:23–29

Scott RI, (2003) Influence of processing on the roll forming characteristics of recovery annealed steel, PhD thessis, Deakin University, 2003

Abvabi A, Rolfe B, Hodgson P, Weiss M, (2013) Development of an inverse routine to predict residual stresses in the material based on a bending test, Trans Tech Pub, in Proceedings of 16th ESAFORM Conference on Material Forming, Stafa-Zurich, Switzerland. vol 554. pp. 949–956

Mendiguren J, Abvabi A, Rolfe B, Weiss M (2015) Improvement of accuracy in a free bending test for material characterization. Int J Mech Sci 103:288–296

Sun Y, (2019)A novel method to measure residual stress of cold-rolled thin sheets via pure benidng approach, Chinese patent, 2019

Sun Y, Li Y, Daniel WJ, Meehan PA, Liu Z, Ding S (2017) Longitudinal strain development in chain-die forming AHSS products: analytical modelling, finite element analysis and experimental verification. J Mater Process Technol 243:322–334

Moen CD, Igusa T, Schafer BW (2008) Prediction of residual stresses and strains in cold-formed steel members. Thin-Walled Struct 46:1274–1289

Cao J, Gharghouri MA, Nash P (2016) Finite-element analysis and experimental validation of thermal residual stress and distortion in electron beam additive manufactured Ti-6Al-4 V build plates. J Mater Process Technol 237:409–419

Halicioglu R, Dulger LC, Bozdana AT (2016) Structural design and analysis of a servo crank press. Engineering Science and Technology, an International Journal 19:2060–2072

Halicioglu R, Dulger LC, Bozdana AT (2018) Improvement of metal forming quality by motion design. Robot Comput Integr Manuf 51:112–120

Hutchings MT, Withers PJ, Holden TM, Lorentzen T, (2005) Introduction to the characterization of residual stress by neutron diffraction. Taylor&Francis, London 2005

Kirstein O, Luzin V, Garbe U (2009) The strain-scanning diffractometer Kowari. Neutron News 20:34–36

Sun Y, Luzin V, Daniel WJ, Meehan PA, Zhang M, Ding S (2017) Development of the slope cutting method for determining the residual stresses in roll formed products. Measurement 100:26–35

Vajragupta N, Wechsuwanmanee P, Lian J, Sharaf M, Münstermann S, Ma A et al (2014) The modeling scheme to evaluate the influence of microstructure features on microcrack formation of DP-steel: the artificial microstructure model and its application to predict the strain hardening behavior. Comput Mater Sci 94:198–213

Acknowledgments

The authors acknowledge Baosteel Co. Ltd. for providing the material properties of the experimental samples. This project is financially supported by Baosteel-Australia Joint Research and Development Centre (BAJC) BA17013 and ANSTO Bragg Institute beam time proposal 4865 and 6499. The authors also would like to acknowledge the assistance of Emeritus Professor J.L. Duncan, Mr Zhen Qian, Mr Chang Wang and Mr Kang An in writing this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, Y., Luzin, V., Khan, S. et al. Understanding of residual stresses in chain-die-formed dual-phase (DP) metallic components: predictive modelling and experimental validation. Int J Adv Manuf Technol 103, 3337–3360 (2019). https://doi.org/10.1007/s00170-019-03671-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03671-9