Abstract

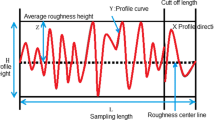

Dynamic surface roughness prediction during metal cutting operations plays an important role to enhance the productivity in manufacturing industries. Various machining parameters such as unwanted noises affect the surface roughness, whatever their effects have not been adequately quantified. In this study, a general dynamic surface roughness monitoring system in milling operations was developed. Based on the experimentally acquired data, the milling process of Al 7075 and St 52 parts was simulated. Cutting parameters (i.e., cutting speed, feed rate, and depth of cut), material type, coolant fluid, X and Z components of milling machine vibrations, and white noise were used as inputs. The original objective in the development of a dynamic monitoring system is to simulate wide ranges of machining conditions such as rough and finishing of several materials with and without cutting fluid. To achieve high accuracy of the resultant data, the full factorial design of experiment was used. To verify the accuracy of the proposed model, testing and recall/verification procedures have been carried out and results showed that the accuracy of 99.8 and 99.7 % were obtained for testing and recall processes.

_

A dynamic surface roughness monitoring system in milling operations of Al 7075 and St 52 is developed based on the ANNs using cutting conditions, vibrations in X and Z directions, and cutting fluid as inputs and surface roughness as output.

Similar content being viewed by others

References

Hedberg GK, Shin YC, Xu L (2015) Laser-assisted milling of Ti-6Al-4V with the consideration of surface integrity. Int J Adv Manuf Technol 79(9-12):1645–1658

Imran M et al (2015) Assessment of surface integrity of Ni superalloy after electrical-discharge, laser and mechanical micro-drilling processes. Int J Adv Manuf Technol 79(5-8):1303–1311

Parenti P et al (2015) A model-based approach for online estimation of surface waviness in roll grinding. Int J Adv Manuf Technol 79(5-8):1195–1208

Wang T, Xie L, Wang X (2015) Simulation study on defect formation mechanism of the machined surface in milling of high volume fraction SiCp/Al composite. Int J Adv Manuf Technol 79(5-8):1185–1194

Zhao Q et al (2015) Tool life and hole surface integrity studies for hole-making of Ti6Al4V alloy. Int J Adv Manuf Technol 79(5-8):1017–1026

Altug M, Erdem M, Ozay C (2015) Experimental investigation of kerf of Ti6Al4V exposed to different heat treatment processes in WEDM and optimization of parameters using genetic algorithm. Int J Adv Manuf Technol 78(9-12):1573–1583

Ghobadi S et al (2015) Developing a fuzzy multivariate CUSUM control chart to monitor multinomial linguistic quality characteristics. Int J Adv Manuf Technol 79(9-12):1893–1903

Khorasani AM, Aghchai AJ, Khorram A (2011) Chatter prediction in turning process of conical workpieces by using case-based resoning (CBR) method and Taguchi design of experiment. Int J Adv Manuf Technol 55(5-8):457–464

Oktem H, Erzurumlu T, Erzincanli F (2006) Prediction of minimum surface roughness in end milling mold parts using neural network and genetic algorithm. Mater Des 27(9):735–744

Liu T-I, Jolley B (2015) Tool condition monitoring (TCM) using neural networks. Int J Adv Manuf Technol 78(9-12):1999–2007

Elgargni M, Al-Habaibeh A, Lotfi A (2015) Cutting tool tracking and recognition based on infrared and visual imaging systems using principal component analysis (PCA) and discrete wavelet transform (DWT) combined with neural networks. Int J Adv Manuf Technol 77(9-12):1965–1978

Gupta A et al (2015) Optimisation of turning parameters by integrating genetic algorithm with support vector regression and artificial neural networks. Int J Adv Manuf Technol 77(1-4):331–339

Benardos P, Vosniakos GC (2002) Prediction of surface roughness in CNC face milling using neural networks and Taguchi’s design of experiments. Robot Comput Integr Manuf 18(5):343–354

Risbood K, Dixit U, Sahasrabudhe A (2003) Prediction of surface roughness and dimensional deviation by measuring cutting forces and vibrations in turning process. J Mater Process Technol 132(1):203–214

Zain AM, Haron H, Sharif S (2010) Prediction of surface roughness in the end milling machining using artificial neural network. Expert Syst Appl 37(2):1755–1768

Özel T, Hsu T-K, Zeren E (2005) Effects of cutting edge geometry, workpiece hardness, feed rate and cutting speed on surface roughness and forces in finish turning of hardened AISI H13 steel. Int J Adv Manuf Technol 25(3-4):262–269

Huang BP, Chen JC, Li Y (2008) Artificial-neural-networks-based surface roughness Pokayoke system for end-milling operations. Neurocomputing 71(4):544–549

Topal ES (2009) The role of stepover ratio in prediction of surface roughness in flat end milling. Int J Mech Sci 51(11):782–789

Ezugwu E et al (2005) Modelling the correlation between cutting and process parameters in high-speed machining of Inconel 718 alloy using an artificial neural network. Int J Mach Tools Manuf 45(12):1375–1385

Özel T, Karpat Y (2005) Predictive modeling of surface roughness and tool wear in hard turning using regression and neural networks. Int J Mach Tools Manuf 45(4):467–479

Lalwani D, Mehta N, Jain P (2008) Experimental investigations of cutting parameters influence on cutting forces and surface roughness in finish hard turning of MDN250 steel. J Mater Process Technol 206(1):167–179

Brezocnik M, Kovacic M, Ficko M (2004) Prediction of surface roughness with genetic programming. J Mater Process Technol 157:28–36

Baek DK, Ko TJ, Kim HS (2001) Optimization of feedrate in a face milling operation using a surface roughness model. Int J Mach Tools Manuf 41(3):451–462

Öktem H, Erzurumlu T, Kurtaran H (2005) Application of response surface methodology in the optimization of cutting conditions for surface roughness. J Mater Process Technol 170(1):11–16

Ho W-H et al (2009) Adaptive network-based fuzzy inference system for prediction of surface roughness in end milling process using hybrid Taguchi-genetic learning algorithm. Expert Syst Appl 36(2):3216–3222

Lo S-P (2003) An adaptive-network based fuzzy inference system for prediction of workpiece surface roughness in end milling. J Mater Process Technol 142(3):665–675

Ho S-Y et al (2002) Accurate modeling and prediction of surface roughness by computer vision in turning operations using an adaptive neuro-fuzzy inference system. Int J Mach Tools Manuf 42(13):1441–1446

Jiao Y et al (2004) Fuzzy adaptive networks in machining process modeling: surface roughness prediction for turning operations. Int J Mach Tools Manuf 44(15):1643–1651

Kirby ED, Chen JC, Zhang JZ (2006) Development of a fuzzy-nets-based in-process surface roughness adaptive control system in turning operations. Expert Syst Appl 30(4):592–604

Zhong Z, Khoo L, Han S (2006) Prediction of surface roughness of turned surfaces using neural networks. Int J Adv Manuf Technol 28(7-8):688–693

Wang X, Feng C (2002) Development of empirical models for surface roughness prediction in finish turning. Int J Adv Manuf Technol 20(5):348–356

Reddy NSK, Rao PV (2005) Selection of optimum tool geometry and cutting conditions using a surface roughness prediction model for end milling. Int J Adv Manuf Technol 26(11-12):1202–1210

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khorasani, A., Yazdi, M.R.S. Development of a dynamic surface roughness monitoring system based on artificial neural networks (ANN) in milling operation. Int J Adv Manuf Technol 93, 141–151 (2017). https://doi.org/10.1007/s00170-015-7922-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7922-4